Description

Product Feature

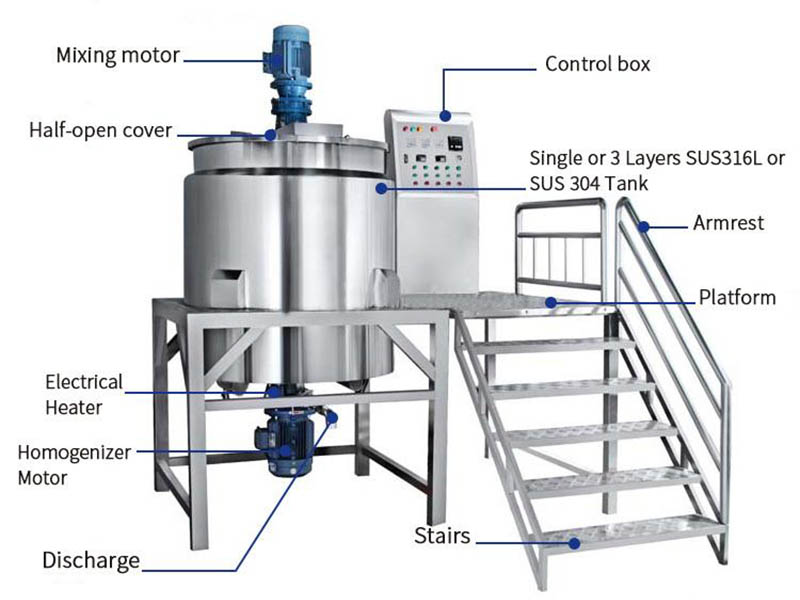

The liquid mixing machine can also be equipped with a platform. The control cabinet is designed and installed on the platform. The heating, mixing speed and heating time are all completed on the same operation plane, which is simple and efficient! When the material enters the mixing tank, it is stirred through the adjustable variable speed paddle in the tank to make the material fully mixed and evenly mixed. At the same time of mixing, the materials are heated or cooled by electric heating in the jacket.

1. PME Liquid washing homogenizing mixer adopts single-direction or double-direction scraping blending and frequency. conversion speed adjustment, so as to satisfy product of different technological requirements.

2. According to technological requirements, the materials can be heated or cooled. The heating method can be chosen steam or electric heating according to customer.

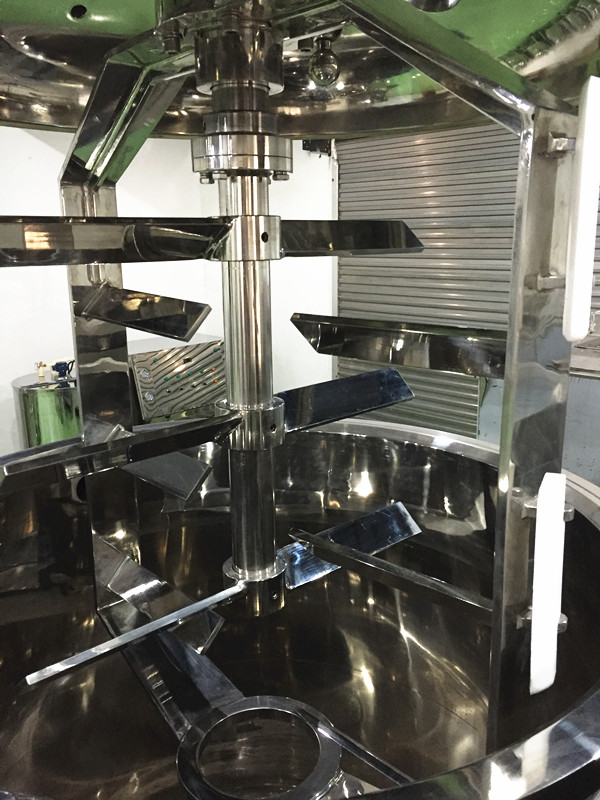

3. Various forms of blending vanes are suitable for production of different types of products.

4. Made of imported SUS306L or SUS304, the tank body and pipe are carried out mirror polishing.

5. Vacuum pump can be equipped to carry out vacuum defoaming (optional).

6. Bottom installation type dispersing head and emulsifying head are optional to speedup dissolution and emulsification of materials.

7. The stainless steel electric control cabinet can completely supervise the operation of equipment, and display data, such temperature and blending rotation speed etc.

Application

The liquid mixing machine is suitable for the reaction and mixing of different mucus such as mutual mixing, dissolution and uniform mixing. The mixing system adopts one-way or two-way scraping mixing and frequency conversion speed regulation. The pot body can be heated and cooled, which is suitable for the production of different process requirements. Applicable to liquid washing, textile auxiliaries, medicine and health care, food and beverage, spices, essence, fine chemicals and other industries

Shampoo

Conditioner

Shower gel

Detergent

Hand sanitizer

Product Details

Single direction mixing with scraper

Paddle mixing with guide plate

Two different directions mixing with scraper

Two different direction mixing with helicon mixing with scraper

Homogenizer is SINA EKATO Patent;

Patent (Patent no: ZL 2016 2 0382415.4 ZL 2016 3 0157070.8)

Warning: Below Homogenizer Photo Forbid Pass to any of SINAEKATO competitor or supplier; THANK YOU FOR COOPERATION;

Schneider electrical components & Siemens motor & Siemens inverter

Stainless Steel 304 Platform & Stair – Slippery-proof type:

Projects

Cooperative Customers

Reviews

There are no reviews yet.