Description

Machine Video

Applicable

| Daily cosmetic | |||

| hair conditioner | facial mask | moisturizing lotion | suncream |

| skin care | shea butter | body lotion | sunscreen cream |

| cream | hair cream | cosmetic paste | BB Cream |

| lotion | face wash liquid | mascara | foundation |

| hair color | face cream | eye serum | hair gel |

| hair dye | lip balm | serum | lip gloss |

| emulsion | lipstick | highly viscous product | shampoo |

| cosmetic toner | hand cream | shaving cream | moisturizing cream |

| Food&Pharmaceutical | |||

| cheese | milk butter | ointment | ketchup |

| mustard | peanut butter | mayonnaise | wasabi |

| toothpaste | margarine | Salad dressing | sauce |

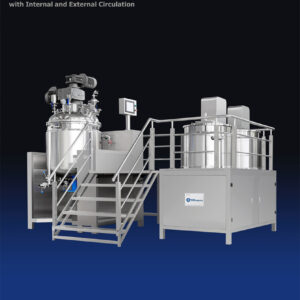

Performance & Features

1.For material of super high viscosity (above 50,000 C.P.S), the high viscosity vacuum emulsifying homogenizer is highly recommonded.

2.Raw materials can be directly sucked into the groove by the machine The machine is equipped with vacuum, hydraulic pressure, heating,cooling and other functions.

3.Emulsifying, blending and dispersion can be completed within a short period of time.

4.Slow speed blade type blending and high speed homogenizing systems are provided with frequency conversion control.

5.Users can select push button control or PLC touch screen system.

6.Parts that contact materials are made of stainless steel SS316L. The whole equipment conforms to GMP standard. Blending is carried out under vacuum to effectively ensure the emulsifying effect.

7.The machine equipped with CIP, which can convenient user’s own CIF system to clean the machine.

Technical Parameter

| Model | Capacity | Homogenizer Motor | Stir Motor | Dimension | Total power | Limit vacuum(Mpa) | |||||

| KW | r/min | KW | r/min | Length(mm) | Width(mm) | Height(mm) | Steam heating | Electric heating | |||

| SME-D5 | 5L | 0.37 | 3000 | 0.18 | 63 | 1260 | 540 | 1600/1850 | 2 | 5 | -0.09 |

| SME-D10 | 10L | 0.75 | 3000 | 0.37 | 63 | 1300 | 580 | 1600/1950 | 3 | 6 | -0.09 |

| SME-D50 | 50L | 3 | 3000 | 1.1 | 63 | 2600 | 2250 | 1950/2700 | 9 | 18 | -0.09 |

| SME-D100 | 100L | 4 | 3000 | 1.5 | 63 | 2750 | 2380 | 2100/2950 | 13 | 32 | -0.09 |

| SME-D200 | 200L | 5.5 | 3000 | 2.2 | 63 | 2750 | 2750 | 2350/3350 | 15 | 45 | -0.09 |

| SME-D300 | 300L | 7.5 | 3000 | 2.2 | 63 | 2900 | 2850 | 2450/3500 | 18 | 49 | -0.085 |

| SME-D500 | 500L | 11 | 3000 | 4 | 63 | 3650 | 3300 | 2850/4000 | 24 | 63 | -0.08 |

| SME-D1000 | 1000L | 15 | 3000 | 5.5 | 63 | 4200 | 3650 | 3300/4800 | 30 | 90 | -0.08 |

| SME-D2000 | 2000L | 15 | 3000 | 7.5 | 63 | 4850 | 4300 | 3800/5400 | 40 | _ | -0.08 |

| Note: In case of inconformity of the data in the table due to technical improvement or customization, the real object shall prevail | |||||||||||

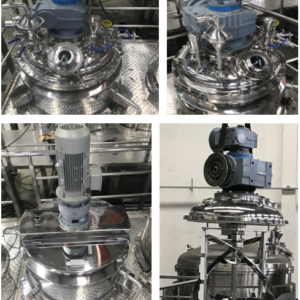

Product Details

high speed emulsfying head 3000 r/min shear fineness achievenomter scale adopt intemational brand motors use frequency conversion speed control mixing , so as to get high-quality products customized styles can bemade accroding to material requirements

anchor stirrer spiral ribbon stiming anchor stimer oil-water pot pre-treatment system water phase and oil phase pot to pre-heat and disperse the raw materials.

then transfer them to main pot to begin production Hermetic vacuum Defoaming throught the vacuum system can meet the requirements for the aseptic and high standard product

Console the control panel displays and controls the equipment, mixing homogenization, pressure data, etc . in real time Electric box

Use internationally renowned brand components to ensure the quality of the equipment and longer service life

The homogenizing stirring system of SME-D bidirectional stirring vacuum emulsifier is composed of high-speed homogenizer shear, center stirring paddle and scraping stirring frame. High shear homogenizer can quickly refine the material. When it comes to sticky products, the stirring function of the single homogenizer is not so significant, but with the center mixing and box scraping of two-way mixing, the high-speed shear of the homogenizer can be faster and more efficient, and the full volume of materials can be quickly stirred without dead corners.

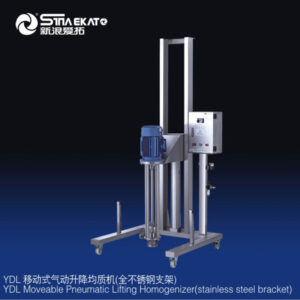

Relevant Machines

We can offer machines for you as following :

(1)Cosmetics cream ,ointment ,skin care lotion ,toothpaste production line

From Bottle washing machine -bottle drying oven -Ro pure water equipment -mixer -filling machine -capping machine -labeling machine -heat shrink film packing machine -inkjet printer -pipe and valve etc

(2)Shampoo,liquid saop ,liquid detergent(for dish and cloth and toilet etc ) ,liquid wash production line

(3)Perfume production line

(4)And other machines ,powder machines ,lab equipment ,and some food and chemical machines

Bottle Drying Oven

Aseptic Storage Tank

Filling Machine

Labeling machine

Packing machine

Packaging & Delivery

Packaging Details: Standard Export Plywood Case/ Steel Case,

Suitable Size for Container Transportation

Delivery Detail:60 days

COMPANY PROFILE

With the solid backing of Jiangsu Province Gaoyou City Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKATO Chemical Machinery Co., Ltd. is a professional manufacturer of various types of cosmetic machinery and equipment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, food, chemical industry, electronics, etc., serving many nationally and internationally famous enterprises such as Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., Ltd., Liangmianzhen Group, Zhongshan Perfect, Zhongshan Jiali, Guangdong Yanor, Guangdong Lafang, Beijing Dabao, Japan Shiseido, Korea Charmzone, France Shiting, USA JB, etc.

Materials Source:

80% of the main parts of our products are provided by world’s famous suppliers.During long-term cooperation and exchange with them,we have accumulated much valuable experience,so that we can provide customers with high quality products and more effective guarantee

Cooperative client

Material Certificate

Contact person

Ms Jessie Ji

Mobile/What’s app/Wechat: +86 13660738457

Email: 012@sinaekato.com

Official website: http://www.sinaekato.group/

Reviews

There are no reviews yet.