On a rainy afternoon in the busy city of GaoYou city Baqiao town industrial park, the Member of China Daily Chemical Association gathered for a special visit to the Sina Ekato factory. As industry leaders and representatives from various cosmetic companies gathered, the event promised insights into the vacuum emulsifying mixer technology that has been taking the cosmetic world by storm.

.jpg) Visit our Communist China Daily-use Chemical Association Committee will set up the China Daily-use Chemical Association Intelligent Manufacturing Industry Committee and intelligent leading high-quality development Forum in Gaoyou the next day. Mr. Xu Yu tian, Chairman of sina ekato, and Mr. Tan You min, chief engineer of SINA EKATO, will attend this conference. Mr. Tan You min will present his latest research report (Intelligent Online Cold emulsion Technology Solution for High concentration surfactants).

Visit our Communist China Daily-use Chemical Association Committee will set up the China Daily-use Chemical Association Intelligent Manufacturing Industry Committee and intelligent leading high-quality development Forum in Gaoyou the next day. Mr. Xu Yu tian, Chairman of sina ekato, and Mr. Tan You min, chief engineer of SINA EKATO, will attend this conference. Mr. Tan You min will present his latest research report (Intelligent Online Cold emulsion Technology Solution for High concentration surfactants).

The China Cosmetic Committee, a renowned organization responsible for regulating and promoting the cosmetic industry in the country, organized this visit to provide its members with a deeper understanding of the advancements and innovations in cosmetic manufacturing. The committee’s focus on quality production and technological advancements made Sina Ekato, a leading manufacturer and supplier of cosmetic equipment, the obvious choice for this enlightening experience.

The China Cosmetic Committee, a renowned organization responsible for regulating and promoting the cosmetic industry in the country, organized this visit to provide its members with a deeper understanding of the advancements and innovations in cosmetic manufacturing. The committee’s focus on quality production and technological advancements made Sina Ekato, a leading manufacturer and supplier of cosmetic equipment, the obvious choice for this enlightening experience.

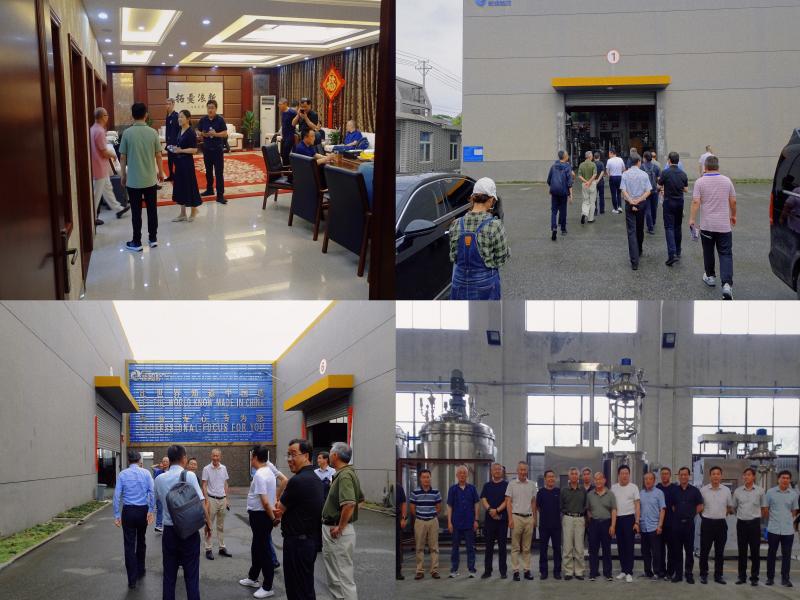

The day began with a warm welcome from Sina Ekato’s management team, who expressed their appreciation for the committee’s continuous support and dedication to the cosmetic industry. They highlighted the long-standing partnership between Sina Ekato and the committee, which has resulted in mutually beneficial collaborations and shared knowledge.

The day began with a warm welcome from Sina Ekato’s management team, who expressed their appreciation for the committee’s continuous support and dedication to the cosmetic industry. They highlighted the long-standing partnership between Sina Ekato and the committee, which has resulted in mutually beneficial collaborations and shared knowledge.

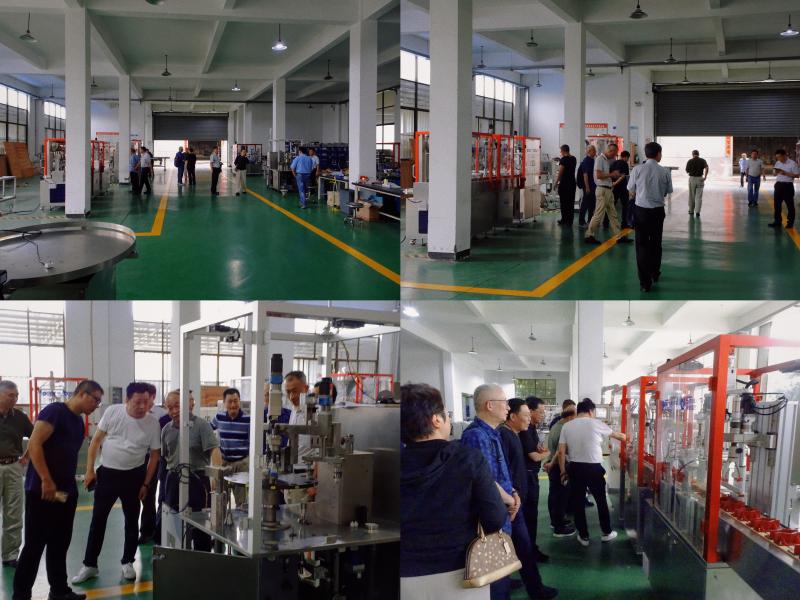

Then, the participants were shown around the factory by the chairman, which had an unmistakable atmosphere of technological sophistication. It was immediately evident that the company’s commitment to innovation was deeply ingrained in its operations. The buzzing of state-of-the-art machinery filled the air as the visitors observed the manufacturing process of vacuum emulsifying mixers – a core component of the cosmetic manufacturing process.

Then, the participants were shown around the factory by the chairman, which had an unmistakable atmosphere of technological sophistication. It was immediately evident that the company’s commitment to innovation was deeply ingrained in its operations. The buzzing of state-of-the-art machinery filled the air as the visitors observed the manufacturing process of vacuum emulsifying mixers – a core component of the cosmetic manufacturing process.

The vacuum emulsifying mixer, a revolutionary technology in the cosmetic industry, has become synonymous with efficiency and quality. Its ability to combine ingredients such as oils, water, and powders under vacuum conditions ensures optimal product quality, stability, and homogeneity. This advanced technology has led to the development of superior cosmetics that meet the ever-increasing demands of consumers.

The vacuum emulsifying mixer, a revolutionary technology in the cosmetic industry, has become synonymous with efficiency and quality. Its ability to combine ingredients such as oils, water, and powders under vacuum conditions ensures optimal product quality, stability, and homogeneity. This advanced technology has led to the development of superior cosmetics that meet the ever-increasing demands of consumers.

During the factory tour, Sina Ekato’s experts demonstrated the various stages of the mixing process, showcasing the intricacies involved in achieving the desired consistency and texture of cosmetic products. The visitors were impressed by the precision and speed at which the vacuum emulsifying mixers operated, ensuring consistent results and minimizing production time.

During the factory tour, Sina Ekato’s experts demonstrated the various stages of the mixing process, showcasing the intricacies involved in achieving the desired consistency and texture of cosmetic products. The visitors were impressed by the precision and speed at which the vacuum emulsifying mixers operated, ensuring consistent results and minimizing production time.

The visit concluded with a panel discussion, facilitated by the committee, allowing attendees to interact with Sina Ekato’s experts. Industry professionals exchanged valuable insights on the challenges faced by cosmetic manufacturers and the latest trends shaping the industry. This engaging dialogue highlighted the importance of ongoing collaboration between manufacturers and regulatory bodies to ensure the production of safe and effective cosmetic products.