Description

Application

- Cosmetics: As mentioned earlier, a semi-auto cap screw machine is commonly used in the cosmetics industry to tighten caps onto cosmetic containers such as bottles, jars, or tubes.

- Pharmaceuticals: In the pharmaceutical industry, a semi-auto cap screw machine can be utilized to secure caps on medicine bottles, vials, or other medication containers.

- Food and beverage: Cap screw machines can be found in the food and beverage industry, where they are used to seal caps on bottles, jars, or containers for products like sauces, condiments, beverages, or preserves.

- Home care and cleaning products: Manufacturers of home care and cleaning products often utilize semi-auto cap screw machines to tighten caps onto their products, such as detergents, disinfectants, or household cleaners.

Performances and Farameter

- Cap feeding: The machine is equipped with a cap feeding mechanism that supplies caps to the screwing station. This can be done manually by loading caps into a hopper or automatically using a cap sorting system.

- Cap alignment: The machine ensures that the caps are properly positioned before screwing. It may employ mechanisms such as tracks, chutes, or vibratory bowls to align the caps and present them to the screwing station.

- Screw application: The machine applies torque to tighten the caps securely onto the cosmetic containers. It usually includes a screwing station with adjustable settings for torque control. The screwing operation can be performed by hand or using a motorized driver.

- Adjustment for different cap sizes: A semi-auto cap screw machine can be adjusted to accommodate various cap sizes commonly used in cosmetics. This is typically achieved by changing the settings or using interchangeable parts, such as cap chucks or jaws.

- Speed and control: The machine operates at adjustable speeds to match the desired production rate. It may have a control panel or interface to set parameters such as screwing speed and torque levels.

- Stability and support: The machine provides stability and support for the containers during the cap screwing process. This can be done using fixtures, clamps, or other mechanisms to hold the containers in place.

- Safety features: These machines often have safety features to protect operators during the cap screwing operation. Examples include emergency stop buttons, safety guards, or sensors that detect obstructions or malfunctions.

- User-friendly operation: Semi-automatic cap screw machines typically offer user-friendly features, making it easy for operators to load caps, adjust settings, and perform routine maintenance. Clear instructions and indicators guide the operator through the process.

Relevant Machine

- Bottle Washing Machine

- Bottle Drying Sterilizer

- RO Water Machine

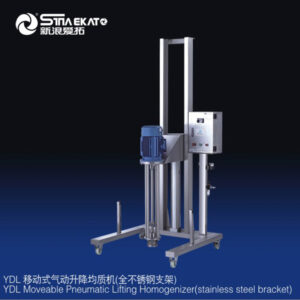

- Vacuum Homogenizer mixer

- Cream and paste Filling machine

- shrinking seal wrapping machine

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, foodchemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

Workshop Production

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Our Project

Packing and Shipping

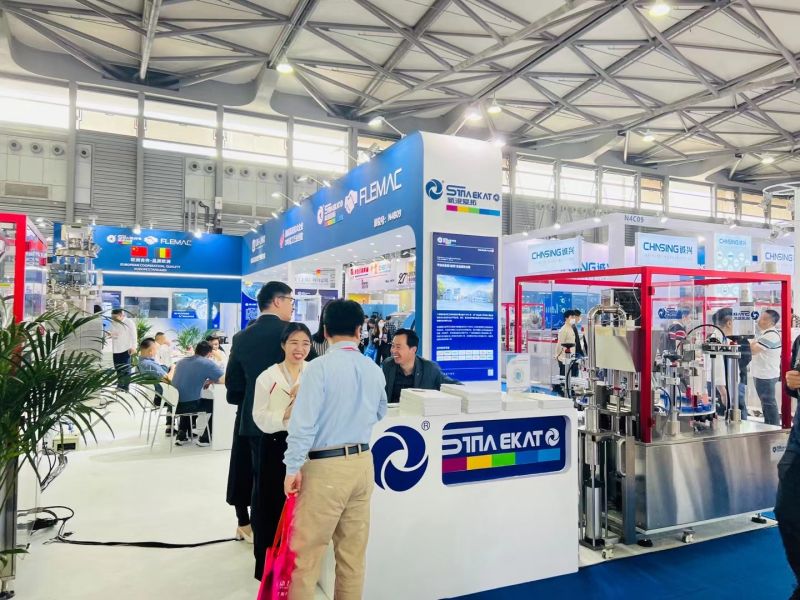

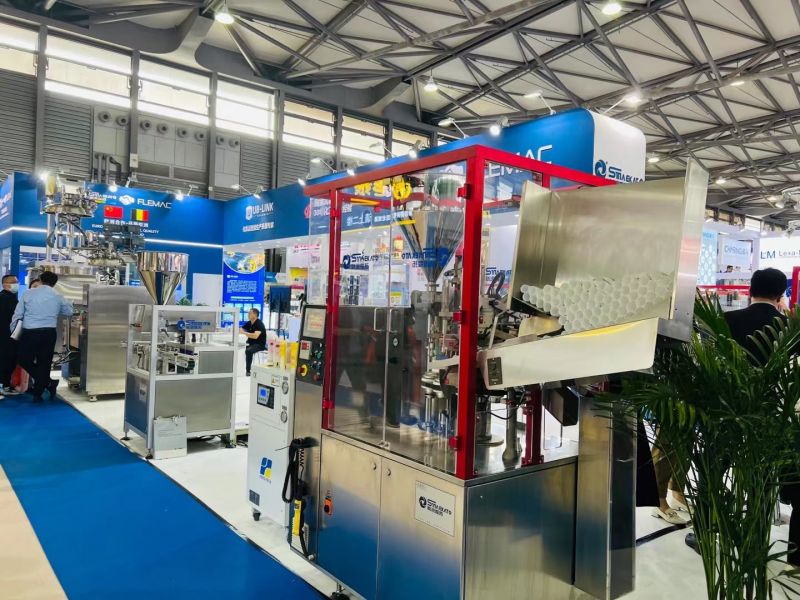

Exhibitions & Customers visit factory

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

Reviews

There are no reviews yet.