Description

Application

This machine is mainly used for composite hose, plastic tube is a quantitative filling, packing container material and sealing, this machine is widely used in pharmaceutical, chemical, food, chemical and other industries packaging. Such as cream, skin cream, toothpaste, shoe polish, glue, AB glue, epoxy glue, hair coloring agent, etc., liquid or cream filling and sealing.

Working principle Artificial

The tube is inserted into the sockets and goes through mechanical transmission, allowing for automatic rotation of eight stations. When the tube is detected by the photoelectric device, quantitative filling takes place. If there is no tube, filling does not occur. Following filling, the tube goes through heating, sealing, and batch number printing. Finally, the product is launched and packaged.

Performances And Features

1.Tube Loading: The operator manually loads empty laminated tubes into the machine’s tube holders or loading tray.

2.Tube Orientation: The machine automatically orients the tubes in a specific position to ensure accurate filling and sealing.

3.Filling: The machine uses a filling mechanism to dispense the desired product, such as cream, gel, or ointment, into the tubes. The filling process can be controlled by the operator, ensuring the correct amount of product is filled into each tube.

4.Tube Sealing: After filling, the machine seals the open end of the tube using various sealing methods. Common sealing techniques include heat sealing or ultrasonic sealing, depending on the type of laminated tube and product being filled

5.Date and batch coding: Some machines may include a mechanism for integrating date and batch coding onto the tubes during the sealing process for traceability purposes.

6.Tube Ejection: After sealing, the machine ejects the filled and sealed tubes from the machine for further processing, such as labeling or packaging.

Technical Parameter

| Model | GZF-= |

| Voltage | AC 220V 50Hz |

| Power consumption | 150w*8 (Tube heating) |

| Air supply | 0.6-0.8(Mpa) |

| Gas Consumption | <30 (dm³/min) |

| Filling range | 5-250(ml) (can be customized) |

| Working capacity | 20-40 (b/min.) |

| Measurement precision | <2% |

| Machine size | 1230*700*1400mm |

| Machine weight | 230kg |

Product Details

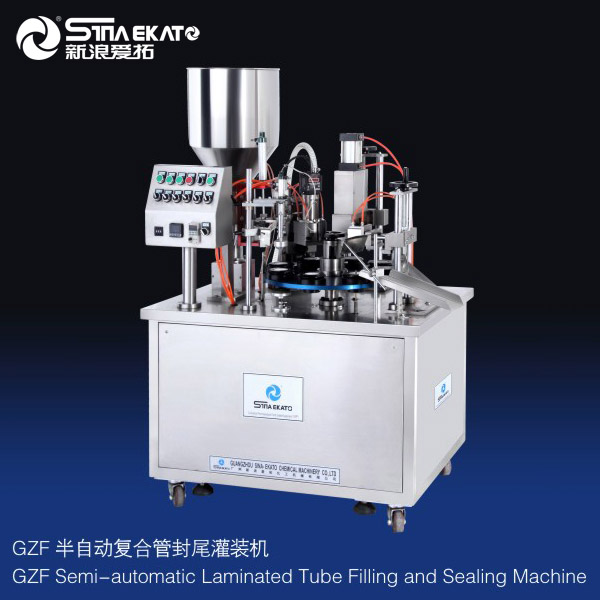

GZF Semi-automatic laminated Tube Filling and Sealing Machine

Control cabinet Button control Emergency stop Easy operate Frequency converter speed regulation SUS304L Stainless steel

Hopper: SUS316 Stainless steel hopper

Color Code: Photoelectric detection of the tube

Filling Nozzle :Regular filling volume5-250g Filling volume can be customized High precision filling head quantitative filling

Blowing: Blowing capacity can be adjusted.

Inner Heating: Heating temperature can be adjusted

Outer Heating: Heating temperature can be adjusted

Cutting Tail: cutting the tube tail Sealing the tube

Date printer: Can print the date send one set of number and one set of alphabet for free

Relevant Machines

We can offer machines for you as following

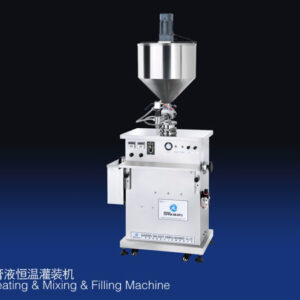

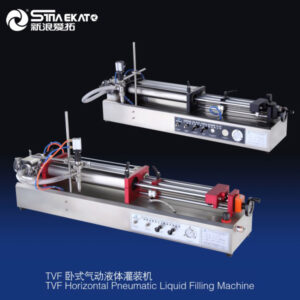

Reverse osmosis water purifier, vacuum homogenizing emulsifier. aseptic storage tank, drying sterilizer, ointment filling machine. conveying workbench, code printer, labeling machine, aluminum foil sealing machine, shrink film machine

Click the picture to jump to the link related to the product

- RO Water Machine

- Bottle Washing Machine

- Bottle Drying Sterilizer

- Vacuum Homogenizer mixer

- Stainless steel storage tank

- Feeder-machine

- Automatic aluminum foil sealing machine

- Labelling Machine

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, foodchemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

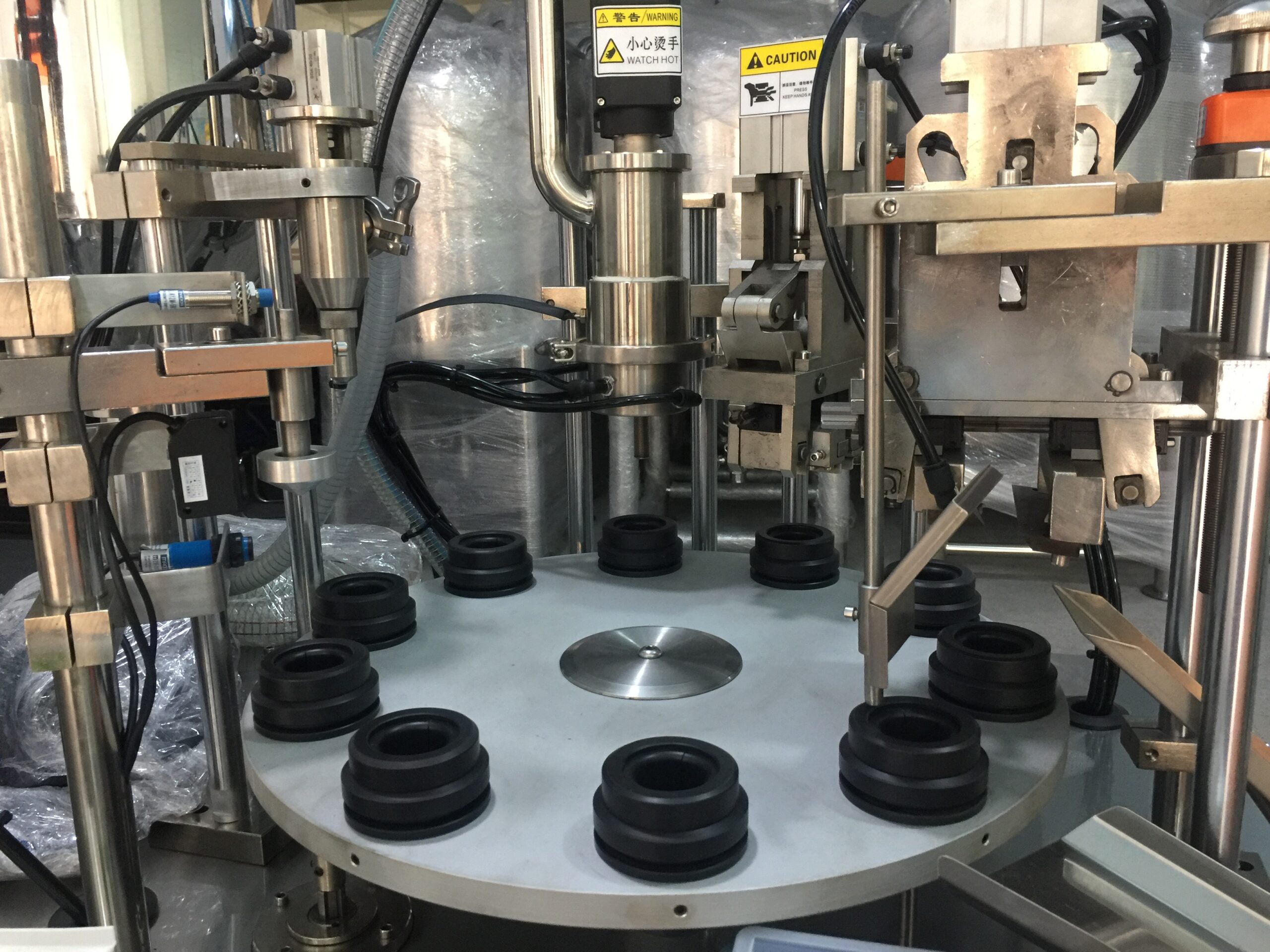

Filling Workshop Production

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

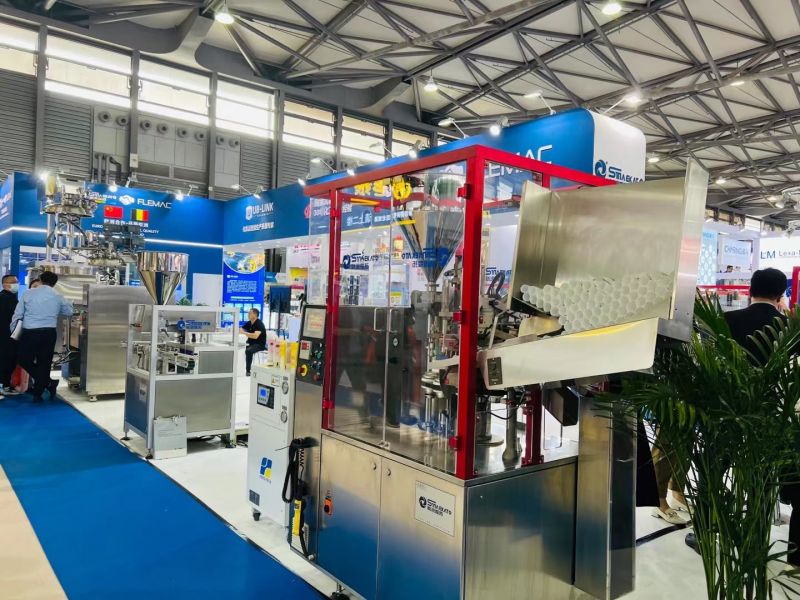

Our Project

Packing and Shipping

Exhibitions & Customers visit factory

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

Reviews

There are no reviews yet.