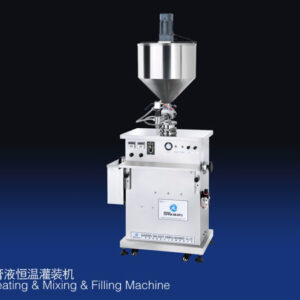

Description

Application

he series of machine is widely suitable for filling and sealing products packed by tubes in such industries as cosmetics, toothpaste, medicine, food, chemical industry, etc.

Working Principle

The high frequency vibration acts on the two inner surfaces of the plastic tube, and the heat generated by the vibration causes these two surfaces to be welded together tightly. The strength of the welded area is the same as that of the original plastic. There is no need for adhesive or heating, which replaces the traditional hot pressing or bonding process. It is a low-cost method that does not lead to pollution or damage to the plastic tube.

Performances And Features

1) High grade LCD programming controller and button combined operation video screen, fully grasp the equipment stepless speed regulation, parameter equipment, output count statistics, pressure indicator, fault display and other operating conditions, so that the operation is simple and user-friendly.

2) The whole process of fully automatic pipe supply, marking, inert temperature gauge (optional), filling, folding, coding and finished products outlet.

3) High precision calibration system reduces the range of color difference between the tube body and the color standard.

4) External adjustment part, position digital display, quick and accurate adjustment (suitable for multi-specification, multi-variety production).

5) Integration of machine, light, electricity and air, no pipe without filling in the real column, the supply pipe is not in place, low pressure, automatic display (alarm); Open the protective door can stop automatically and other automatic functions.

6) If the rejection rate is not caused by the demander’s pipes, the qualified rate of the equipment shall be above 99.5%.

Technical Parameter

| 1) | Model | GZF |

| 2) | Description : | Filling and Sealing Machine |

| 3) | Packaging Speed : | 3,000 – 3,600 pcs / hour |

| 4) | Filling Volume : | 50–200 ml |

| 5) | Power : | 3-phase 4-line socket(380V50HZ) |

| 6) | Electric Machinery Power : | 0.75kw |

| 7) | Heat Up Power : | 4kw |

| 8) | Air Pressure : | 0.5Mpa—0.7Mpa |

| 9) | Max.Air Consumption : | 0.5m3/min |

| 10) | Timing Mode : | Stepless speed regulating |

| 11) | Machine Dimension | 2250*1050*2190mm |

| 12) | G.W. : | 1500 kg |

Product Details

Relevant Machines

We can offer machines for you as following

Reverse osmosis water purifier, vacuum homogenizing emulsifier. aseptic storage tank, drying sterilizer, ointment filling machine. conveying workbench, code printer, labeling machine, aluminum foil sealing machine, shrink film machine

Click the picture to jump to the link related to the product

- RO Water Machine

- Bottle Washing Machine

- Bottle Drying Sterilizer

- Vacuum Homogenizer mixer

- Stainless steel storage tank

- Feeder-machine

- Automatic aluminum foil sealing machine

- Labelling Machine

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, foodchemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

Filling Workshop Production

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Our Project

Packing and Shipping

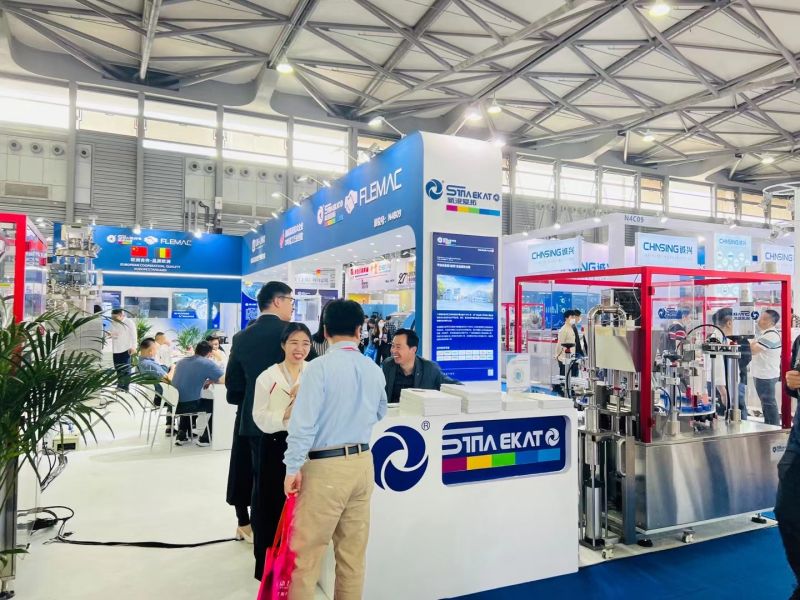

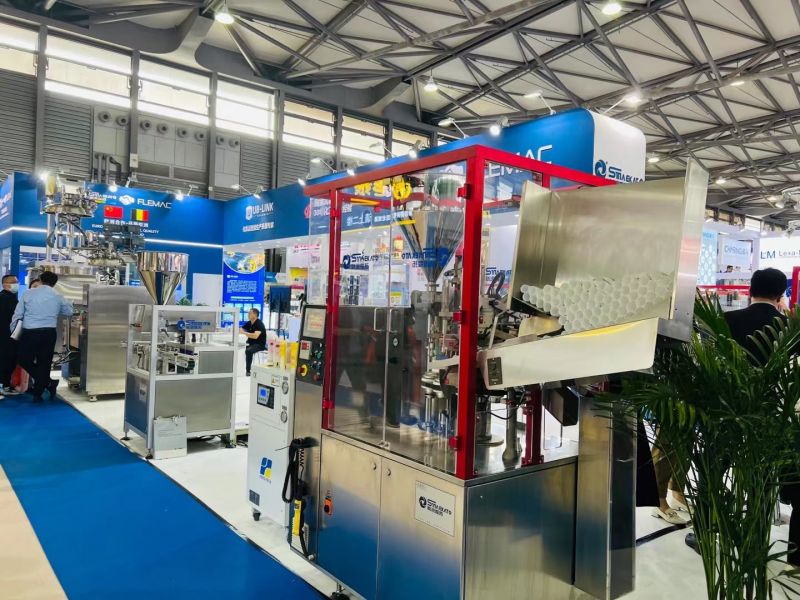

Exhibitions & Customers visit factory

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

Reviews

There are no reviews yet.