For the beauty industry, customer satisfaction is paramount. Beauty product manufacturers are always striving to improve their formulas and ensure that their products meet the high standards set by their customers. To achieve this, many manufacturers rely on vacuum homogenizers, such as the SME-AE Vacuum Homogenizer Emulsifying Mixer of Sina Ekato. This versatile device provides a more outstanding emulsification effect, especially for materials with high base viscosity and solid content. Let’s explore how customers use this the SME-AE vacuum homogenizers to test face creams, BB creams, and sunscreen products.

The SME-AE Homogenizer Emulsifier Blender is designed for Sina Ekato, a trusted brand in the cosmetics industry. This machine ensures that the products produced are of the highest quality and meet customer expectations. Let’s take a closer look at the unique features of this vacuum homogenizer:

The vacuum homogenizing emulsifier is equipped with advanced technology and can accurately control the emulsification process. It creates a vacuum environment that effectively removes air bubbles and moisture from the material, resulting in a smoother, more stable emulsion. This eliminates the risk of product separation or inconsistency, ensuring a high-quality end product.

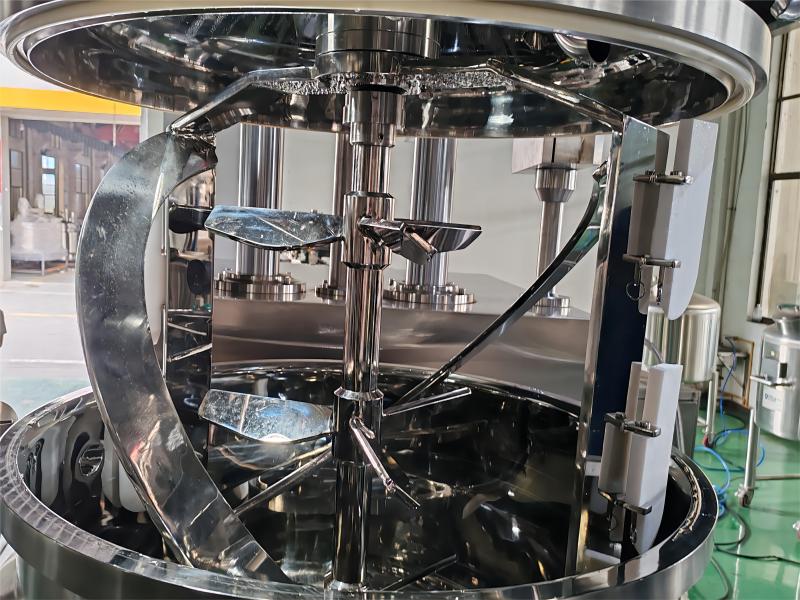

Top-type mixing system: This machine adopts a top-type mixing system with a two-way belt scraper for mixing and wall scraping. This design ensures thorough mixing of ingredients, resulting in a perfectly blended formula. The cosmetics industry demands precision, and this homogenizer delivers exactly that.

Internal circulation system: SME-AE homogenizing emulsifying mixer also includes an internal circulation system with a bottom homogenizer. The system effectively homogenizes ingredients, ensuring uniform texture and consistency. Whether it’s face cream, BB cream or sunscreen, customers can rely on this homogenizer for superior results.

- Sunscreen Production

- BB Cream Production

High-quality structure: The pot body used in this homogenizer is made of imported stainless steel 316L material. This material is known for its durability, corrosion resistance, and hygiene. By using such high-quality materials, SME-AE homogenizer emulsifier mixers are guaranteed to last a long time and adhere to strict hygiene standards.

Comply with GMP standards: The main pot body and premix body of this vacuum homogenizer are made of imported three-layer stainless steel material, and the parts in contact with the material are made of 316L stainless steel. This structure ensures that the machine complies with Good Manufacturing Practice (GMP) standards. Beauty product manufacturers can trust this homogenizer to meet industry regulations and deliver safe products to consumers.

With the SME-AE Homogenizer Emulsifier, customers can confidently test their face creams, BB creams and sunscreen products. This vacuum homogenizer provides a reliable, efficient solution for achieving the texture, consistency and quality your formulations require. It enables manufacturers to try different ingredients and evaluate their effectiveness before bringing the final product to market.

Additionally, vacuum homogenizers simplify the manufacturing process by eliminating the need for multiple pieces of equipment and manual labor. The SME-AE Homogenizer Emulsifier Mixer has advanced features and user-friendly interface, simplifying the production process for beauty product manufacturers, saving time and resources.

In summary, vacuum homogenizers play a vital role in the beauty industry. Manufacturers in the field of face creams, BB creams and sunscreen products rely on these homogenizers to test and improve their formulations. SME-AE Homogenizer Emulsifier Mixers provide an excellent solution for obtaining quality products. With its top-mounted mixing system, internal circulation system, high-quality construction and compliance with GMP standards, this homogenizer ensures customer satisfaction and success in the highly competitive beauty market.