Description

Machine video

Application

Suitable for: food, medicine, cosmetics, chemical industry and other industries of various plastic tube or aluminum plastic pipe filling and tail sealing.

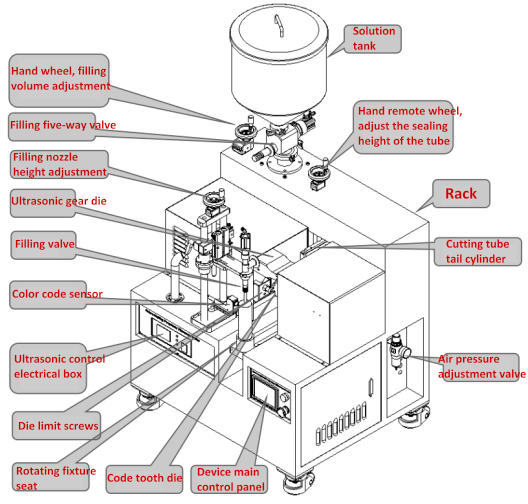

Machine layout

Performances And Features

Titanium alloy screw is used at the connection of the equipment mold and transducer

This equipment is equipped with optical eye induction switch, no tube without sealing

This equipment uses C440 stainless steel cutter

Ultrasonic Sealing Technology: The machine utilizes ultrasonic technology for sealing, providing a reliable and efficient sealing process that ensures the integrity of the filled tubes.

Versatility: The machine is designed to handle a variety of cosmetic products, including creams and pastes, making it suitable for a diverse range of cosmetic manufacturing needs.

Semi-Automatic Operation: The semi-automatic nature of the machine allows for manual control, making it suitable for small to medium-scale production while still offering a degree of flexibility and customization.

Precise Filling: The machine is capable of precise and consistent filling, ensuring uniform product distribution within the tubes for a professional finish.

Adjustable Parameters: The machine offers adjustable parameters for filling and sealing, allowing for customization based on specific product requirements and tube sizes.

Easy to Operate: The machine is designed for user-friendly operation, with intuitive controls and a straightforward setup process.

High-Quality Construction: The machine is built with durable materials and components, ensuring reliability and longevity in a production environment.

Compliance with Standards: The machine may be designed to meet industry standards and regulations for cosmetic production, ensuring product quality and safety.

Technical Parameter

| Power supply | 220v50Hz |

| Air pressure | 0.5Mpa |

| Filling range | 25-250ml |

| Filling accuracy | ±1% |

| Sealing efficiency | 10-15Pcs/Min |

| Sealing diameter | 13-50mm |

| Sealing height | 50~210mm |

| Frequency | 20KHz |

| Power | 2600W |

| Body Materia | SUS 304 |

| Machine weight | 180kgs |

| Machine size | L850*736*1550mm |

Machine configuration

| No | Description | Brand | Origin |

| 1 | Ultrasonic system | Electronic automatic frequency tracking control |

|

| 2 | Electric eye | Panasonic | Japan |

| 3 | PLC | Coolmay | China |

| 4 | Relay | Omron | Japan |

| 5 | Touch Screen | Coolmay | China |

| 6 | Inductive switch | Sick | Germany |

| 7 | Cylinder | AirTAC/Xing Chen | China |

| 8 | Solenoid valve | AirTAC | China taiwan |

| 9 | Stepper motor | Just motion | China |

| 10 | Proximity switch | Omron | Japan |

| 11 | Air source processor | AirTAC | China taiwan |

| 12 | Foot switch | Delixi | China |

Relevant Machines

We can offer machines for you as following

Reverse osmosis water purifier, vacuum homogenizing emulsifier. aseptic storage tank, drying sterilizer, ointment filling machine. conveying workbench, code printer, labeling machine, aluminum foil sealing machine, shrink film machine

Click the picture to jump to the link related to the product

- RO Water Machine

- Bottle Washing Machine

- Bottle Drying Sterilizer

- Stainless steel storage tank

- Automatic aluminum foil sealing machine

- Labelling Machine

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, foodchemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

Filling Workshop Production

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Our Project

Packing and Shipping

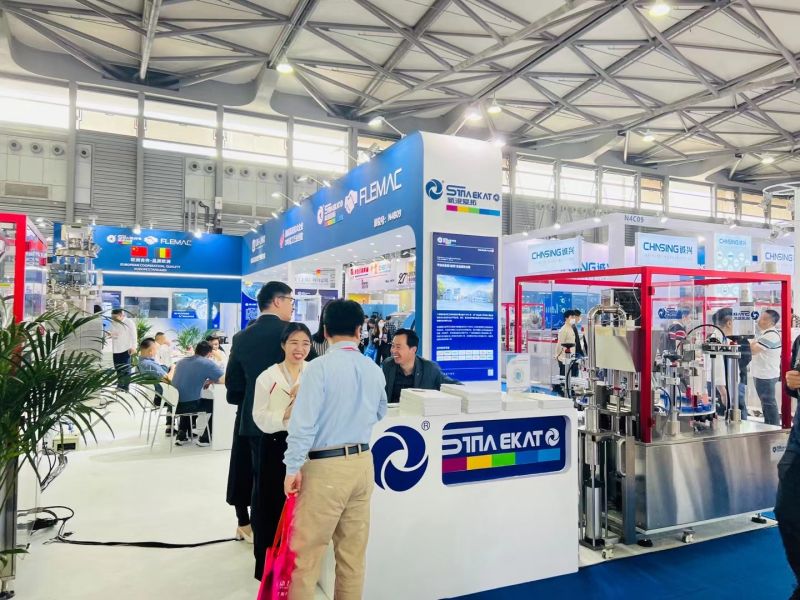

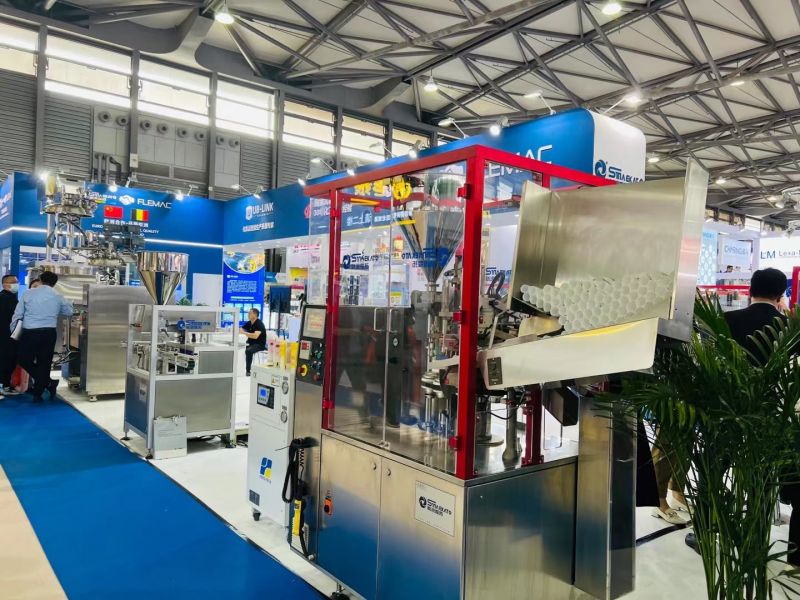

Exhibitions & Customers visit factory

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

-300x300.jpg)

Reviews

There are no reviews yet.