Description

Application

Blender is suitable for the production of various types of detergents cosmetics

spices and other fine chemicals necessary equipment

Features and Advantages

1. The PME-2000L Mixer adopts fixed pot body, pot cover and pot body with flange connection can not be lifted.

1.2The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolve many indissoluble materials such as AES, AESA, LSA, etc.during the liquid detergent production process so as to save energy consumption and shorten production period.

2. The Mixer pot is made of three-layer stainless steel welding, the inner layer in direct contact with the material is made of imported SUS316L stainless steel, the middle jacket layer and the external thermal insulation layer are made of 304 stainless steel, and the tank body and pipeline are mirror-polished or matte, which fully meets the GMP requirements.

3. The stirring system adopts double-direction wall scraping mixing and frequency conversion speed adjustment, so as to satisfy product of different technological requirements

4.The machine adopts the bottom external circulation homogenizing system, the homogenizing motor adopts Germany Siemens, and adjusts the homogenizing machine speed through the PLC control Siemens inverter in the electric cabinet, and the homogenizing speed is 0-2880r/min

5.The machine is controlled by an independent PLC electronic control cabinet, the cabinet is made of imported stainless steel materials, the electrical components are made of Germany Schneider Electric, the inverter and PLC are made of Germany Siemens, the instrument is Omron, and the operation equipment can be monitored through the Siemens PLC touch screen equipment. And through the Siemens touch screen of the cabinet to control the stirring speed, homogenization speed, temperature control and other data

Technical Parameter

| Model | PME-2000L | |

| Working Volume | 2000L | |

| Design Volume | 2500L | |

| Homogenizer | Power(KW) | 17.5KW |

| Motor | Rotate speed(r/min) | 0-2880 r/min |

| Stir Motor (internal Mixing) |

Power(KW) | 5.5KW |

| Rotate speed(r/min) | 0-57r/min | |

| Stir Motor (internal Mixing) |

Power(KW) | 7.5KW |

| Rotate speed(r/min) | 0-33r/min | |

| Overall Dimension(L*W*H) unit(mm) | 2300*2300* | |

| Type of Heating | Steam heating | |

| Note: in case of inconformity of the data in the table due to | ||

| technical improvement or customization, the real object shall prevail. | ||

Product And Details

1.Cover Element

- Single Side Open Cover

2.Top stirring system

- Double-Way Wall Scraper Mixing System

- Top Stirring Motor

3.Bottom External Homogenizer System

Pipe System

Sewage Pipe: This pipe is used to transport wastewater or liquid waste away from the mixer to a suitable disposal or treatment system.

Steam Inlet Pipe: This pipe is responsible for delivering steam into the mixer. Steam can be used for heating and sterilizing the liquid within the mixer.

Cooling Water Inlet Pipe: This pipe provides a flow of cooling water into the mixer to regulate the temperature of the liquid during the mixing process, preventing overheating.

Compressed Air Pipe: This pipe supplies compressed air to the mixer, which may be used for agitation, aeration, or other processes within the mixing chamber.

Steam Outlet Pipe: This pipe is responsible for releasing the steam from the mixer after it has been used in the process.

Cooling Water Outlet Pipe: This pipe is used to remove the cooling water from the mixer after it has served its purpose in regulating the temperature of the liquid.

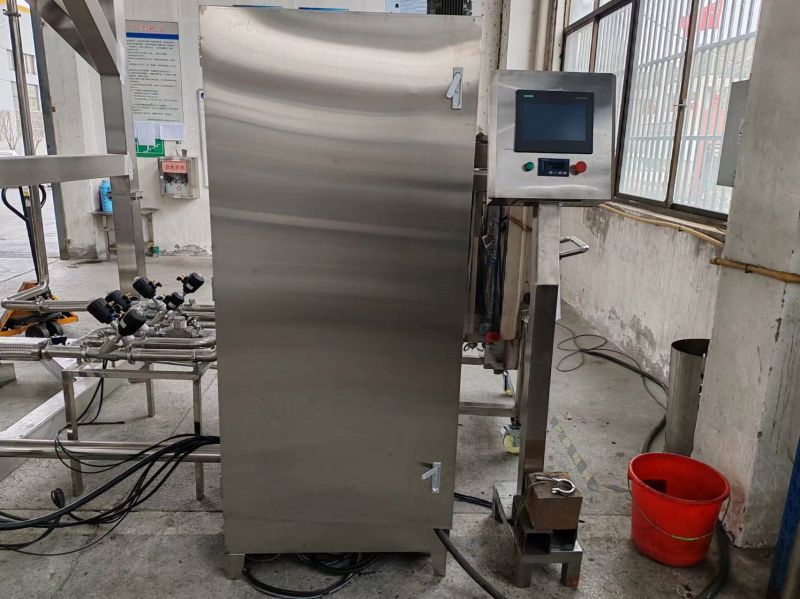

8.Independent PLC control cabinet

8.1 Human-computer interaction system

8.2.PLC control cabinet inside

9.Stainless Steel Platform armrest step (can be customized according to customer factory needs)

Material contacted parts adopts SUS.316All guard bar and platform, frame adopts stainless steel

Related products

We can offer machines for you as following :

(1)Cosmetics cream ,ointment ,skin care lotion ,toothpaste production line

From Bottle washing machine -bottle drying oven -Ro pure water equipment -mixer -filling machine -capping machine -labeling machine -heat shrink film packing machine -inkjet printer -pipe and valve etc

(2)Shampoo, liquid soap ,liquid detergent(for dish and cloth and toilet etc ) ,liquid wash production line

(3)Perfume production line

(4)And other machines ,powder machines ,lab equipment ,and some food and chemical machines

- RO Water Machine

- Bottle Washing Machine

- Bottle Drying Sterilizer

- Stainless steel storage tank

- Cream & Paste Filling Machine

- Labelling Machine

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, food chemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

Workshop Production

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Our Project

Packing and Shipping

- Packing

Exhibitions & Customers visit factory

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

.jpg)

Reviews

There are no reviews yet.