In the bustling world of modern manufacturing, efficiency and precision are paramount. Workshops are constantly seeking innovative solutions to streamline their production processes and enhance product quality. Among the leading names in the emulsifying machine industry, Sina Ekato stands out with its cutting-edge technology and robust machinery. Two of their flagship products, the SME-B 2000L Fixed Emulsifying Machine and the SME Series Hydraulic Lift Emulsifying Machine, are making significant waves in busy workshops around the globe.

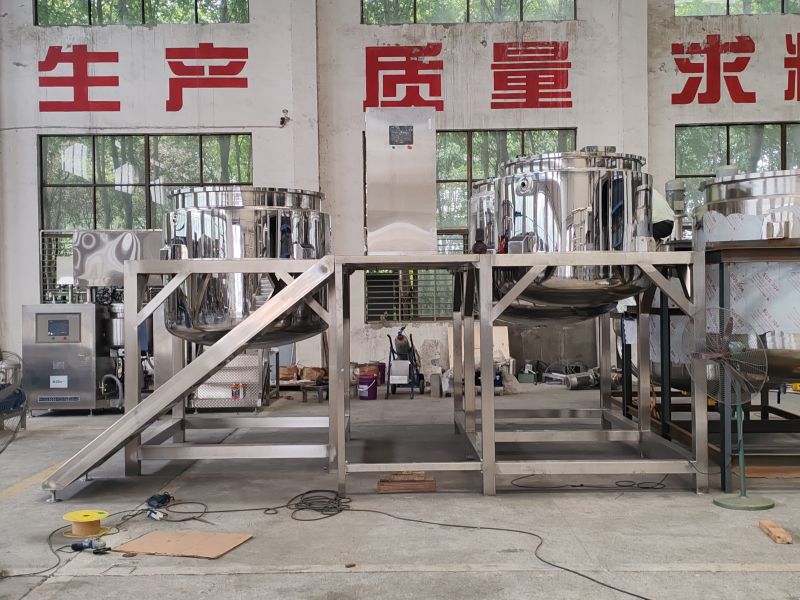

The SME-B 2000L Fixed Emulsifying Machine is a marvel of engineering designed to meet the rigorous demands of high-volume production environments. This machine is specifically tailored for large-scale emulsification processes, making it an ideal choice for industries such as cosmetics, pharmaceuticals, and food production.

One of the standout features of the SME-B 2000L is its fixed design, which ensures stability and consistency during operation. The machine’s robust construction allows it to handle large batches with ease, reducing downtime and increasing overall productivity. In a busy workshop, where every minute counts, the reliability of the SME-B 2000L is a significant advantage.

One of the standout features of the SME-B 2000L is its fixed design, which ensures stability and consistency during operation. The machine’s robust construction allows it to handle large batches with ease, reducing downtime and increasing overall productivity. In a busy workshop, where every minute counts, the reliability of the SME-B 2000L is a significant advantage.

Moreover, the SME-B 2000L is equipped with advanced control systems that enable precise adjustments to emulsification parameters. This level of control ensures that the final product meets the highest quality standards, a critical factor in industries where consistency is key. The machine’s user-friendly interface also simplifies operation, allowing workshop staff to focus on other essential tasks.

While the SME-B 2000L excels in fixed, high-volume applications, the SME Series Hydraulic Lift Emulsifying Machine offers unparalleled versatility. This series is designed to cater to a wide range of production needs, from small batches to medium-scale operations. The hydraulic lift feature is a game-changer, allowing for easy adjustment of the mixing head’s height to accommodate different batch sizes and container types.

While the SME-B 2000L excels in fixed, high-volume applications, the SME Series Hydraulic Lift Emulsifying Machine offers unparalleled versatility. This series is designed to cater to a wide range of production needs, from small batches to medium-scale operations. The hydraulic lift feature is a game-changer, allowing for easy adjustment of the mixing head’s height to accommodate different batch sizes and container types.

In a busy workshop, the ability to quickly switch between different production runs is invaluable. The SME Series Hydraulic Lift Emulsifying Machine’s adaptability ensures that workshops can efficiently handle diverse product lines without the need for multiple machines. This not only saves space but also reduces capital expenditure.

The hydraulic lift mechanism also enhances safety and ergonomics in the workplace. Operators can easily adjust the machine to a comfortable working height, reducing the risk of strain and injury. This focus on operator well-being is a testament to Sina Ekato’s commitment to creating user-friendly and safe equipment.

The hydraulic lift mechanism also enhances safety and ergonomics in the workplace. Operators can easily adjust the machine to a comfortable working height, reducing the risk of strain and injury. This focus on operator well-being is a testament to Sina Ekato’s commitment to creating user-friendly and safe equipment.

Integrating Sina Ekato’s SME-B 2000L Fixed Emulsifying Machine and SME Series Hydraulic Lift Emulsifying Machine into a busy workshop can significantly boost productivity. These machines are designed to work seamlessly together, providing a comprehensive solution for emulsification needs.

In a typical workshop scenario, the SME-B 2000L can handle large-scale production runs, ensuring a steady supply of emulsified products. Meanwhile, the SME Series Hydraulic Lift Emulsifying Machine can be used for smaller, specialized batches or for testing new formulations. This dual approach allows workshops to maintain high output levels while also being agile enough to respond to changing market demands.

In a typical workshop scenario, the SME-B 2000L can handle large-scale production runs, ensuring a steady supply of emulsified products. Meanwhile, the SME Series Hydraulic Lift Emulsifying Machine can be used for smaller, specialized batches or for testing new formulations. This dual approach allows workshops to maintain high output levels while also being agile enough to respond to changing market demands.

Furthermore, the advanced technology and precision engineering of these machines minimize waste and reduce the risk of production errors. This not only saves time and resources but also enhances the overall quality of the final product.

Furthermore, the advanced technology and precision engineering of these machines minimize waste and reduce the risk of production errors. This not only saves time and resources but also enhances the overall quality of the final product.