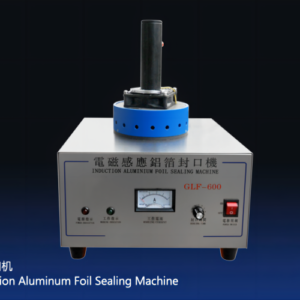

Description

Application

Cosmetic and Personal Care Industry: The machine can be used to seal containers of various cosmetic and personal care products such as lotions, creams, oils and serums, protecting the contents from contamination.

Pharmaceutical Industry: The machine is used to seal pharmaceutical containers such as bottles, vials and jars filled with drugs, syrups or liquid supplements, ensuring product safety and integrity.

Food and beverage industry: The machine is used to seal containers such as jars, bottles and cups for food products such as dairy products, sauces, jams, honey and beverages such as milk, juice and yoghurt.

The automatic aluminum foil sealing machine can achieve fast and efficient sealing, improve product shelf life, prevent leakage, and ensure product safety and hygiene. Its versatility makes it an invaluable asset for various industries requiring reliable, safe product packaging.

Features and Advantages

1.Adjustable sealing parameters: The machine allows the user to adjust the sealing temperature, sealing time and sealing pressure to ensure the best sealing of different types of containers and foil materials.

2.User-friendly interface: The machine is equipped with an easy-to-use control panel or touch screen interface that allows the operator to easily set and adjust sealing parameters.

3.High speed sealing: The machine can quickly seal a large number of containers, increasing the productivity and efficiency of the packaging process.

4.Precise sealing: The machine uses advanced technology to provide accurate and consistent sealing, minimizing the chance of leakage or contamination.

5.Safety features: The machine combines safety features such as sensors and alarms to detect any anomalies during the sealing process, ensuring operator safety and preventing accidents.

6.Compatibility with various container sizes: The machine is designed to accommodate a variety of container sizes, allowing flexibility in sealing different types of products.

7.Versatility: The machine can use different types of aluminum foil, including pre-cut aluminum foil covers or reel aluminum foil, providing versatility in packaging options.

8.Durable construction: The machine is typically made of strong materials that can withstand continuous use in industrial environments and ensure long-lasting performance.

9.Easy maintenance: The machine is designed to be easy to maintain, with accessible components and a simple troubleshooting procedure that minimizes downtime.

Technical Parameter

| Name | Automatic Aluminum foil Sealing machine |

| Power Supply | AC220V±10% 50HZ 2.3KW |

| Sealing diameter(mm) | DN30-DN50mm |

| Sealing height(mm) | 20-350mm |

| Induction head adjustment range | height:0-800mm Front Back:0-260mm |

| Sealing Speed | 80-300Bottles/min |

| Type of cooling | Wind-Cooling |

| Weight | 41.5KG |

| Dimensions(mm) | 700*900*1500mm |

Product Details

1.Simple Control Panel

Digital display of working voltage and current, direct and clear. Simple operation par Concise and clear operation panel, button function at a glance, easy to use.

2.Table height adjustable

The height of the table can be adjusted according to the actual occasion, and the handle is raised or lowered to raise or lower the height. it can also be adjusted back and forth.

3.Rotary Handle

Adjust the height of sealing head through rotating the handle, make it suitable for bottles with different heights. Widen the scope of application.

4.Induction Coil

With pure copper induction coil, it can heat quickly and equally. ensuring that the sealing position would be firm and beautiful. improve production quality.

5.Conveyor belt

Can be used with conveyor belt transported stably and smoothly The width between two rails can be adjusted based on different bottle size.

6.Guide Rails it is used for guiding the bottles, make the mtransported stably and smoothly. The width between two rails can be adjusted based on different bottle size.

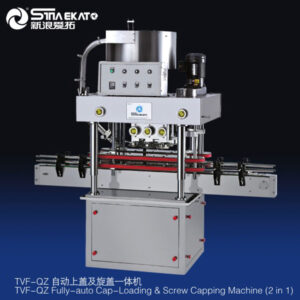

Related products

Foil sealer often match with other machines such as bottle unscrambler filling machine. packing machine, cap sorter, capping machine, labeling machine, cover impressing machine, weight checker, metal detector. inkjet printer etc to combine all kinds of production lines according to requirements

We can offer machines for you as following :

(1)Cosmetics cream ,ointment ,skin care lotion ,toothpaste production line

From Bottle washing machine -bottle drying oven -Ro pure water equipment -mixer -filling machine -capping machine -labeling machine -heat shrink film packing machine -inkjet printer -pipe and valve etc

(2)Shampoo, liquid soap ,liquid detergent(for dish and cloth and toilet etc ) ,liquid wash production line

(3)Perfume production line

(4)And other machines ,powder machines ,lab equipment ,and some food and chemical machines

- RO Water Machine

- Bottle Washing Machine

- Bottle Drying Sterilizer

- Stainless steel storage tank

- Labelling Machine

- Vacuum Homogenizer mixer

- TVF-QZ-Six-head-Automatic-Liquid-Filling-Machine

- Liquid Washing Homogenizing Mixer

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, foodchemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

Workshop Production

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Our Project

Packing and Shipping

- Packing

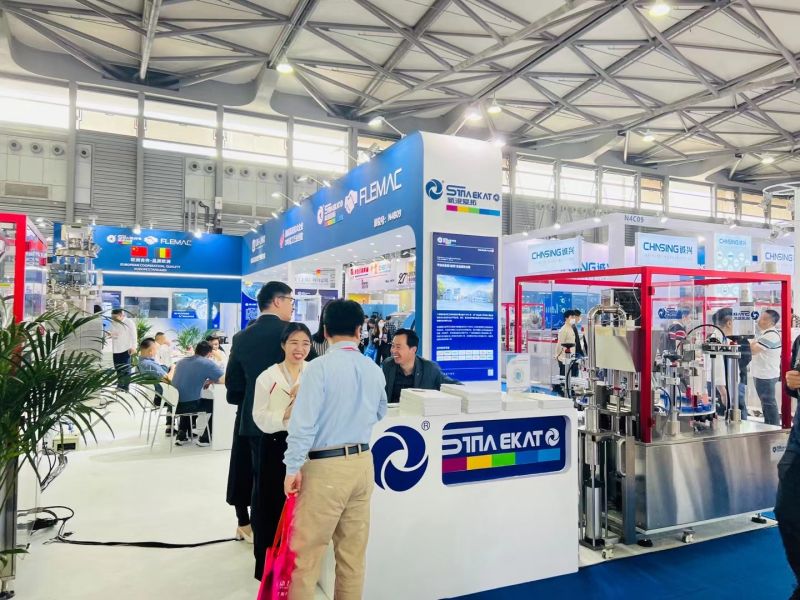

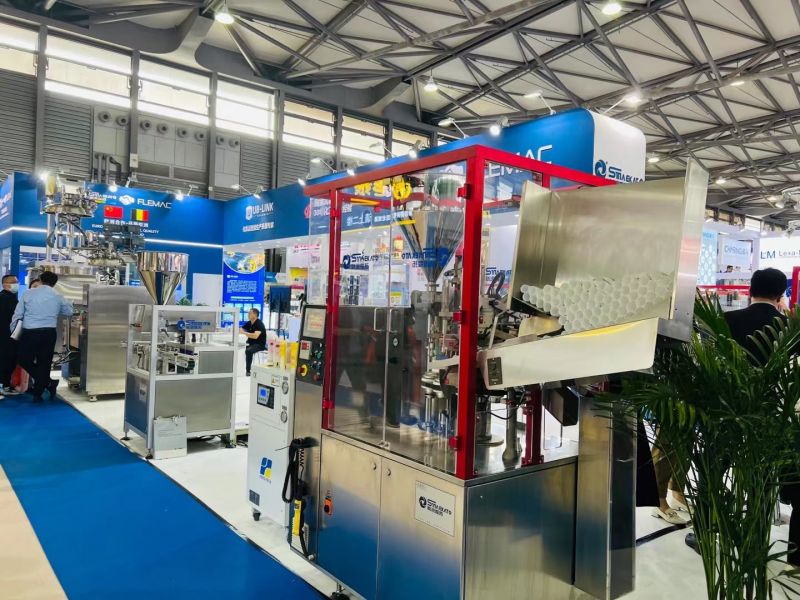

Exhibitions & Customers visit factory

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

Reviews

There are no reviews yet.