Description

Application

The automatic lipstick filling machine is a specialized equipment designed to streamline the process of filling lipstick tubes with lipstick formulation. It is commonly used in cosmetic manufacturing facilities and beauty product factories to efficiently produce high volumes of lipsticks. This machine automates the filling process, ensuring accurate and consistent fill volumes. It eliminates the need for manual filling, reducing labor costs and minimizing the risk of errors or contamination.

Features and Advantages

1. the machine airframe adopt aggravating extruded aluminum type material is made, meticulously meticulous design, appearance beautiful generous, accord with mechanics principle.

2.316 L stainless steel double material barrels (internal and external polishing) every oil heating material bucket USES mixing and temperature control.

3. filling of the mechanical action, precise stepper motor for the device provides accurate filling quantitatively, its rotation Angle, accurate to 0.02 degrees

4. the man-machine intelligence and electric heating system, adopting PLC control the whole action process, make the machine more human, simple and clear the interface make the operation more simple, fever is a temperature control instrument with high-tech control system, the whole system can also control temperature 20 group, a reduction of manipulating the complex and cumbersome, bring the whole stability of the excellent heat system.

Technical Parameter

|

Name: |

12-nozzle Lipstick Filling Machine | ||

|

Specifications: |

Dimensions: |

850mm (L) x 900mm (W) x 1100mm(H) | |

|

Power Souce: |

ØAC220 | ||

|

Air Pressure: |

4~6kg/cm2 | ||

|

Capacity: |

About 6-7 moulds / min. | ||

|

Introduction: |

This machine is mainly for filling lipstick in traditional metal tubes, and cold filling lip gross, lip balm and so on. | ||

|

Target Products: |

Lipstick, Lip Gloss, Lip Balm and so on. | ||

Product And Details

Filling Head

Servo piston filling structure is adopted to ensure accurate filling, and heat recovery function is adopted to improve product quality after filling

Conveyor Track

Adopt the unique mold conveying mechanism, so that the mold into the machine, keep the same freezing time.to achieve a unified standard.

Stripper Machine

Man-machine interface control. convenient adjustment of parameters automatic man-machine interface control, convenient adjustment of parameters, automatic grasp of the cover of the silicone mold. Demoulding process adopts servo motor control lifting, to ensure accurate demoulding.

Related products

We can offer machines for you as following :

(1)Cosmetics cream ,ointment ,skin care lotion ,toothpaste production line

From Bottle washing machine -bottle drying oven -Ro pure water equipment -mixer -filling machine -capping machine -labeling machine -heat shrink film packing machine -inkjet printer -pipe and valve etc

(2)Shampoo, liquid soap ,liquid detergent(for dish and cloth and toilet etc ) ,liquid wash production line

(3)Perfume production line

(4)And other machines ,powder machines ,lab equipment ,and some food and chemical machines

- RO Water Machine

- Bottle Washing Machine

- Bottle Drying Sterilizer

- Stainless steel storage tank

- SME-65L-Lipstick-Machine

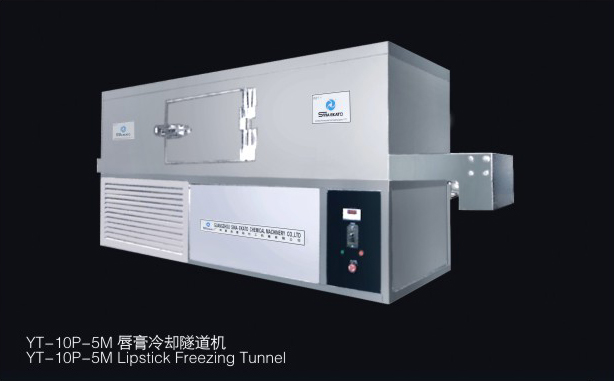

- Lipstick-Freezing-Tunnel

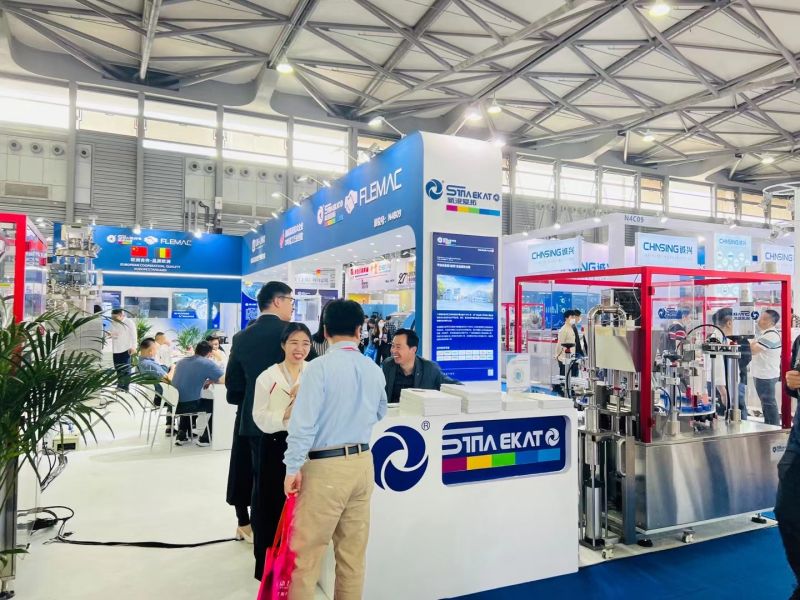

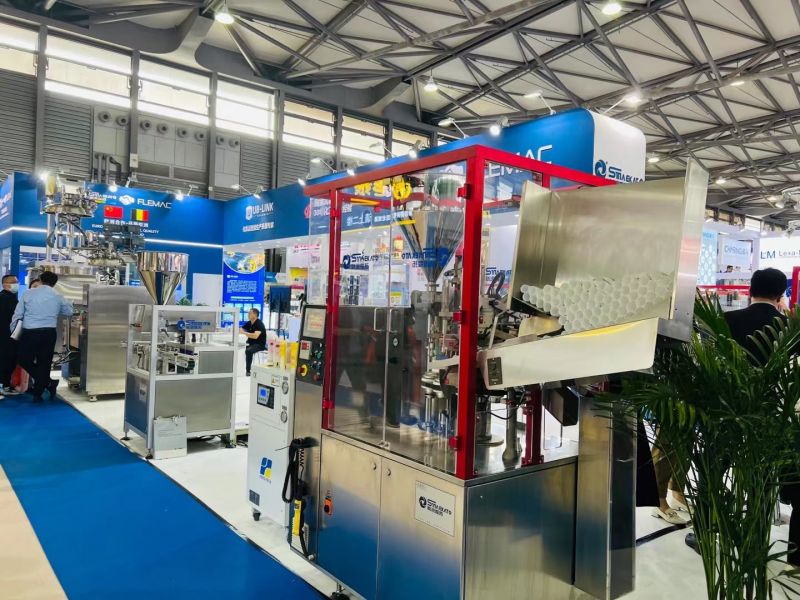

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, food chemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

Workshop Production

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Our Project

Packing and Shipping

- Packing

Exhibitions & Customers visit factory

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

Reviews

There are no reviews yet.