Description

Application

This bottle unscrambler machine is mainly used for automatically sorting, scrambling and conveying the glass or plastic bottles,including round and square bottles. The unscrambling machine can be connected with the labeling machine, filling machine and capping machine by conveyor, realizing a full production line for bottle packaging.

Performance And Features

1.Entire machine design is more optimized for more convenient operation and maintain.

2.Key components are specially designed: Reliable and durable.

3.Good machine structure for more stable working. 5. Multiple safety protection devices to prevent accidents.

4. It is suitable for round glass or plastic bottles automatic transmission, can be connected to labeling machine, filling machine and capping machine etc production line to finish automatic feeding, improving efficiency;

5. Can be applied to the intermediate connection of the assembly line, as a buffer platform, the length of the conveyor belt can be shortened;

6. The applicable bottle range can be adjusted freely. The conveying speed is 30~200 bottles/min. The speed can be adjusted sleeplessly to facilitate production arrangement.

7. Putting on, collecting and sorting products, reducing labor intensity and improving efficiency.

8. The structure is relatively simple, stable and reliable. Mainly used in cosmetics industry, daily chemical industry, pharmaceutical industry and so on

9. Made of the 304 stainless steel, this equipment is made accord with GMP requirements and machine with full welding and polishing workmanship.

Technical Parameters

| Mode | CT-800 | CT-1000 | CT-1200 | CT-1400 |

| Diameter of turning table | 800mm | 1000mm | 1200mm | 1400mm |

| Capacity(cans/min) | 20-40 | 30-60 | 40-80 | 60-12 |

| Overall dimension(mm) | 1180*900*1094 | 1376*110*1094 | 1537*1286*1160 | 1750*1640*1160 |

| Note: In case of inconformity of the data in the table due to technical improvement or customization, the real object shall prevail. | ||||

Product Details

1.Bottle infeed & outlet Directly interface with other machine with adjustable bottle outlet to constitute the packaging production line.Bottle inlet. Inlet Part is wide, you can put multiple bottles at the same time and Bottle Outlet. Outlet Part can be adjustable, according your bottle size to set up the correct position.

2.Motor Famous brand and less noise to ensure stable and durable running.

3.Baffle and Unscramble Mechanism Make changes based on different bottles size; Ensure all various of bottles and cans be transported smoothly. Let the bottle go to the exit quickly and orderly, It saves time and effort.

6.Speed controller & Switch The speed of bottle rotary unscrambel tray is adjustable through the speed controller. One button to operate, easy and simple;

7.Integrate into any kind of production line. Can be combined with weight checker, metal detector, filling machine, capping machine, induction foil sealing machine, labeling machine etc.

Related products

We can offer machines for you as following :

(1)Cosmetics cream ,ointment ,skin care lotion ,toothpaste production line

From Bottle washing machine -bottle drying oven -Ro pure water equipment -mixer -filling machine -capping machine -labeling machine -heat shrink film packing machine -inkjet printer -pipe and valve etc

(2)Shampoo,liquid saop ,liquid detergent(for dish and cloth and toilet etc ) ,liquid wash production line

(3)Perfume production line

(4)And other machines ,powder machines ,lab equipment ,and some food and chemical machines

- RO Water Machine

- Bottle Washing Machine

- Bottle Drying Sterilizer

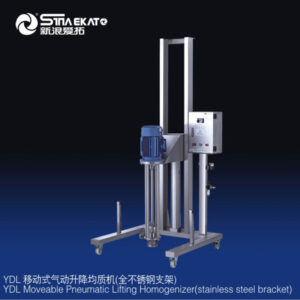

- Vacuum Homogenizer mixer

- Liquid Washing Homogenizing Mixer

- Stainless steel storage tank

- TVF-QZ-Six-head-Automatic-Liquid-Filling-Machine

- Automatic aluminum foil sealing machine

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, foodchemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

Workshop Production

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Our Project

Packing and Shipping

- Packing

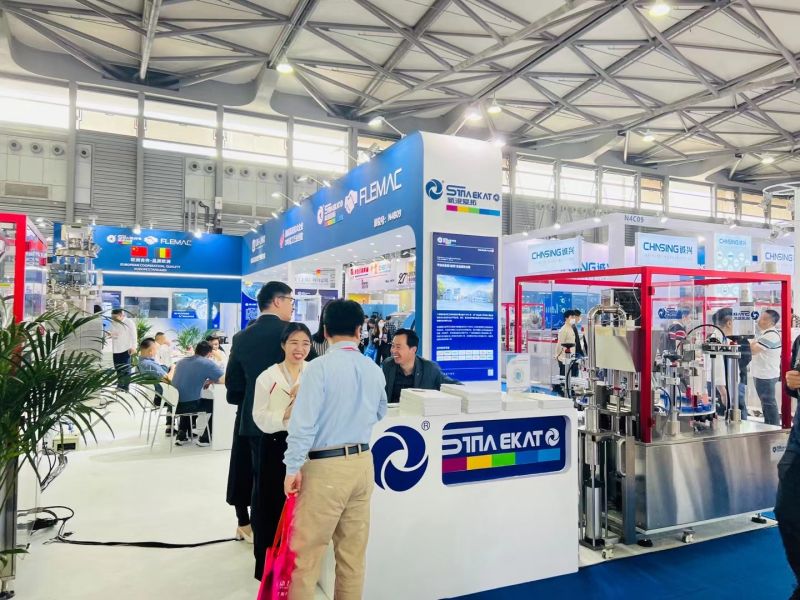

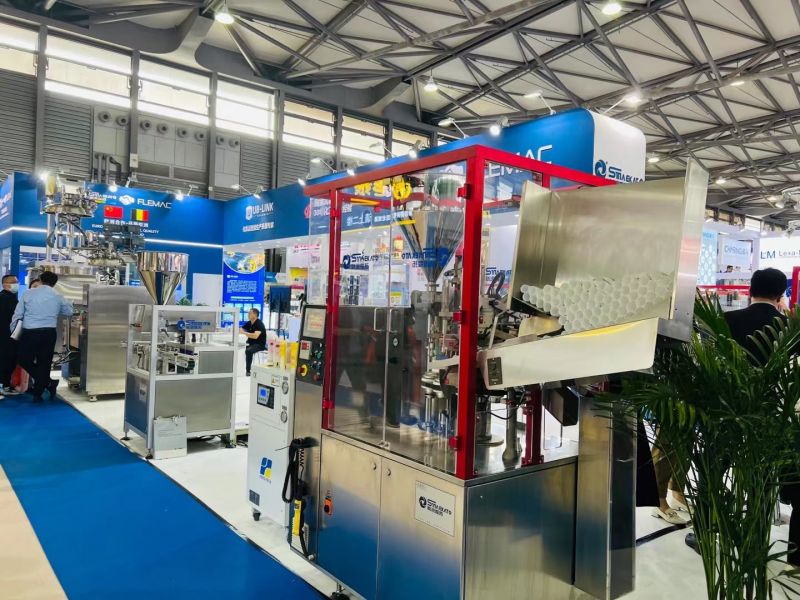

Exhibitions & Customers visit factory

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

Reviews

There are no reviews yet.