Description

Product Introduction

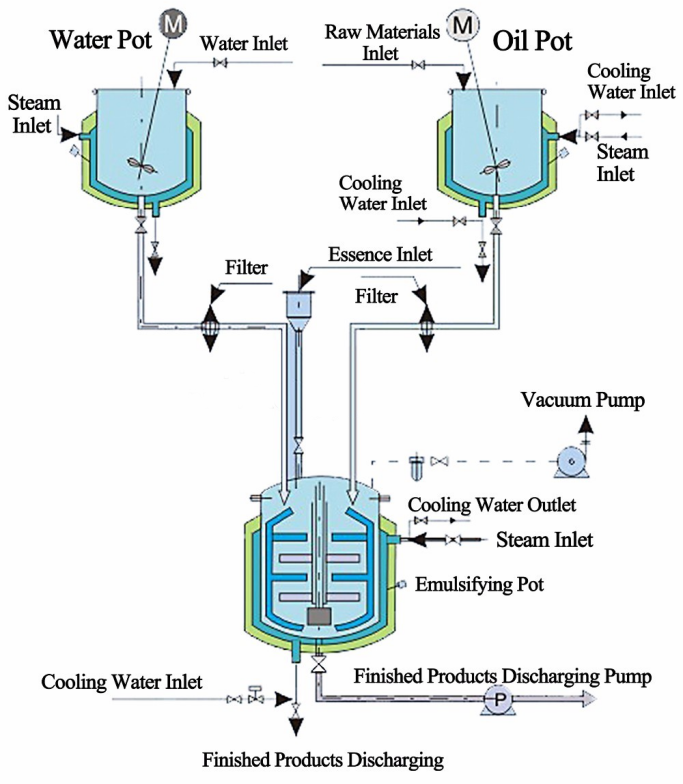

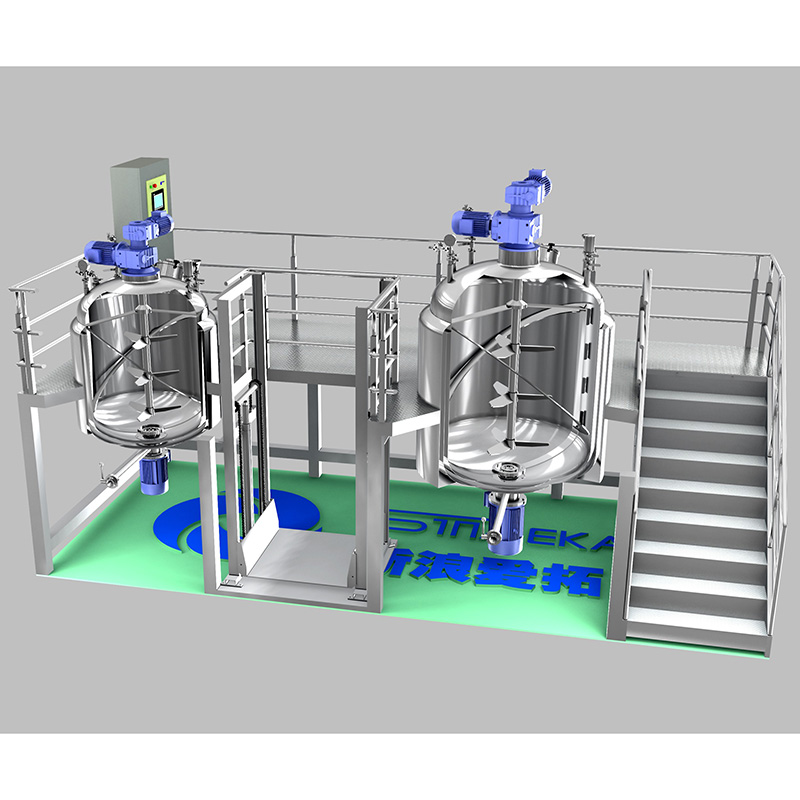

Fixed Vacuum emulsifier mainly by the the main pot, pretreatment pot,vacuum pump, no hydraulic, electrical control systems and other components. The material will be sucked into the main pot for mixing, homogeneous emulsification after been fully dissolved in Water pot and the oil pot (which called pretreatment mixers).

Its main function is the same as lift-type emulsifier with shear, emulsification function. Mainly used in biomedicine; food industry; day care products; paint inks; nano-materials; petrochemicals; dyeing auxiliaries; paper industry; pesticides and fertilizers; plastics and rubber.

Why choose a fixed emulsifier?

1. The height of the plant is relatively low

2. Price more competitive

When the choice of fixed emulsifier, there will be some customers have questions, that is, when finished a pot of material, the workers how to clean the machine?

At the top of the pot we have a CIP shower system. In general, capacity below 500L will have a top sprinkler system, capacity bigger than 500L will have 2-3 sprinkler ball on the lip.With hot water and some solvent,the pot can be cleaned clearly.

Product Feature

1. Cover can not lifting up/down.

2. Heating and Cooling (choose).

3. Top mixing system and bottom homogenizer.

4. Mixer speed variable:0-63rpm

5. Homogenizer speed variable:0-3600rpm.

6. PLC automatic control or manual button control system.

◭ The scraper type agitator mixing adopts the frequency converter for speed adjustment , so that high quality products of different processes according to customer requirements.

◭ The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolve;

(Mainly dissoluble materials such as AES , AESA , LSA , etc. during the liquid detergent production process so as to save energy), consumption and shorten production period. High Shear Homoegnizer adopts German Technology the shear degree is about 0.2~5um.

◭ The tank body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mirror polishing or matte finish , which fully conforms to GMP requirements.

◭ According to customer requirement , the tank can heat and cool materials. The heating way including steam heating and electric heating.

Easy to discharge , bottom direct discharge or by transfer pump.

◭ The emulsifying main tank ,it is vacuum design ,the maximum vacuum degree is -0.09Mpa.

◭ We can choose hydraulic lifting ,it is easy for cleaning. or if factory has limited space,we can advise to fixed type, the top cover can not lifted,but there is pressure manhole,we can open it to check the tank inside .

◭ Oil pot and water pot as pre-heating and pre-mixing,it is necessary for batch production,it efficiently save the preparation time.

Application

Mainly used for lubricating oils skin care products, hair washing products, body washing, hair care, body care, other washing products, sauces, oral liquids.

Lotion

Shampoo

Hair conditioner

Body wash

Mouth wash

Hand sanitizer

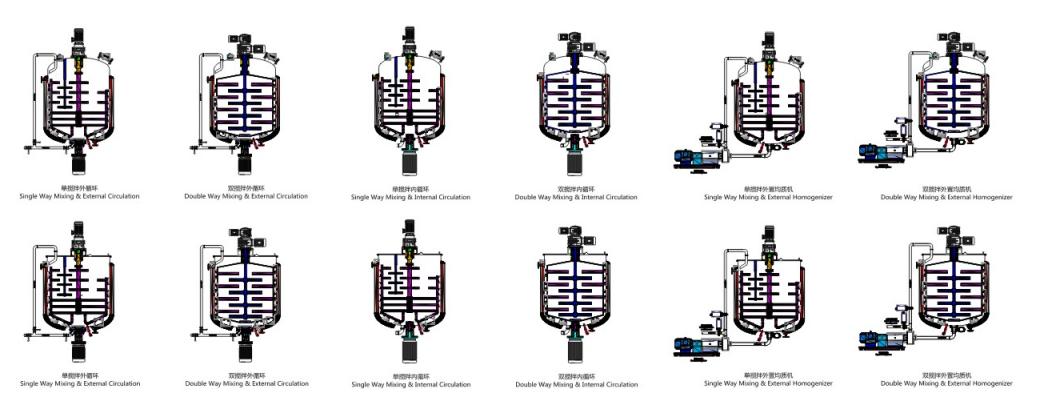

Mixing & Homogenizer Instruction (From Left – Right):

Single Way Mixing & Bottom Homogenizer with circulation – Fixed Pot;

Double Way Mixing & Bottom Homogenizer with circulation – Fixed Pot;

Single Way Mixing & Bottom Homogenizer- Fixed Pot;

Double Way Mixing & Bottom Homogenizer- Fixed Pot;

Single Way Mixing & External Homogenizer with circulation – Fixed Pot;;

Double Way Mixing & External Homogenizer with circulation – Fixed Pot;;

Single Way Mixing & Bottom Homogenizer with circulation – Half-opening Pot;

Double Way Mixing & Bottom Homogenizer with circulation – Half-opening Pot;

Single Way Mixing & Bottom Homogenizer- Half-opening Pot;

Double Way Mixing & Bottom Homogenizer- Half-opening Pot;

Single Way Mixing & External Homogenizer with circulation -Half-opening Pot;;

Double Way Mixing & External Homogenizer with circulation – Half-opening Pot;

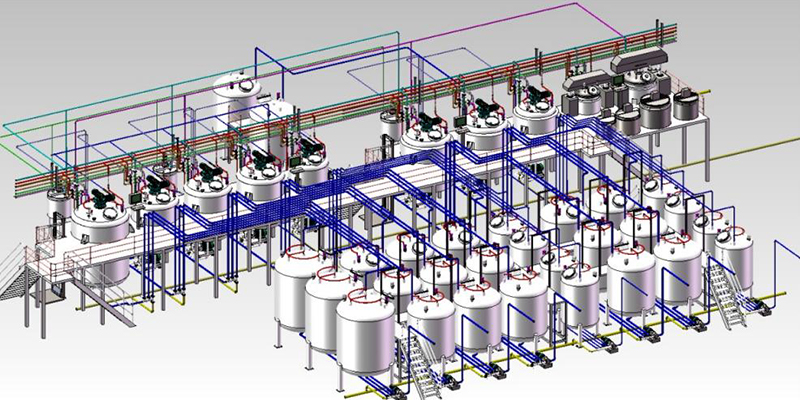

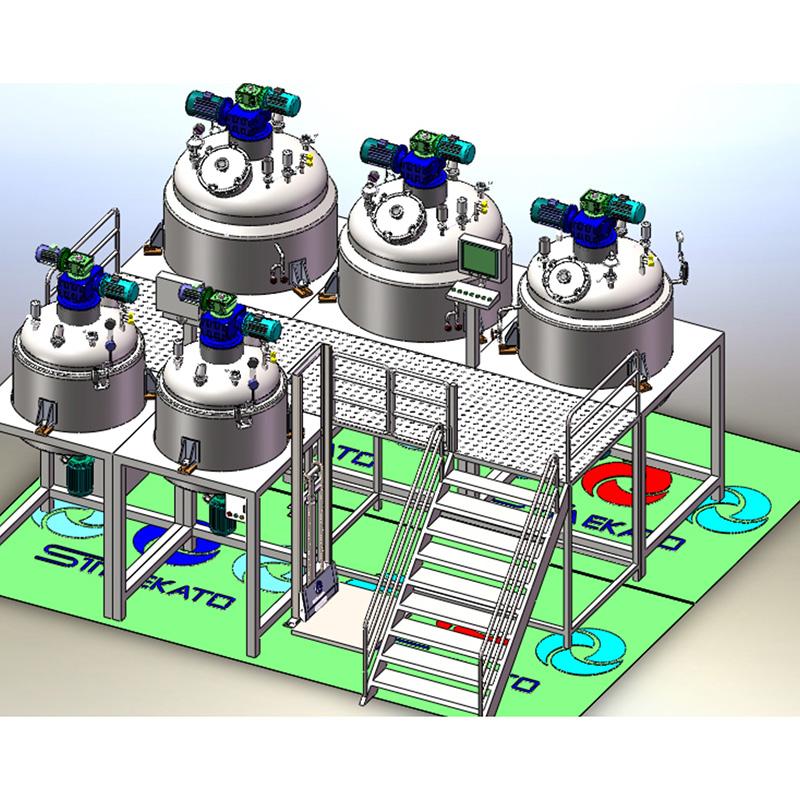

Projects

Cooperative Customers

Reviews

There are no reviews yet.