Description

Application

the Flanged Fixed SME-B 1000L Vacuum Homogenizer Emulsifier Mixer by Sina Ekato is a versatile and efficient solution for companies seeking to optimize their production processes. Whether you are involved in the production of cosmetics, pharmaceuticals, food products, or chemicals, this mixer is designed to meet your specific mixing and homogenizing needs.

|

Daily cosmetic |

|||

| hair conditioner | facial mask | moisturizing lotion | suncream |

| skin care | shea butter | body lotion | sunscreen cream |

| cream | hair cream | cosmetic paste | BB Cream |

| lotion | face wash liquid | mascara | foundation |

| hair color | face cream | eye serum | hair gel |

| hair dye | lip balm | serum | lip gloss |

| emulsion | lipstick | highly viscous product | shampoo |

| cosmetic toner | hand cream | shaving cream | moisturizing cream |

|

Food & Pharmaceutical |

|||

| cheese | milk butter | ointment | ketchup |

| mustard | peanut butter | mayonnaise | wasabi |

| toothpaste | margarine | Salad dressing | sauce |

Performances And Features

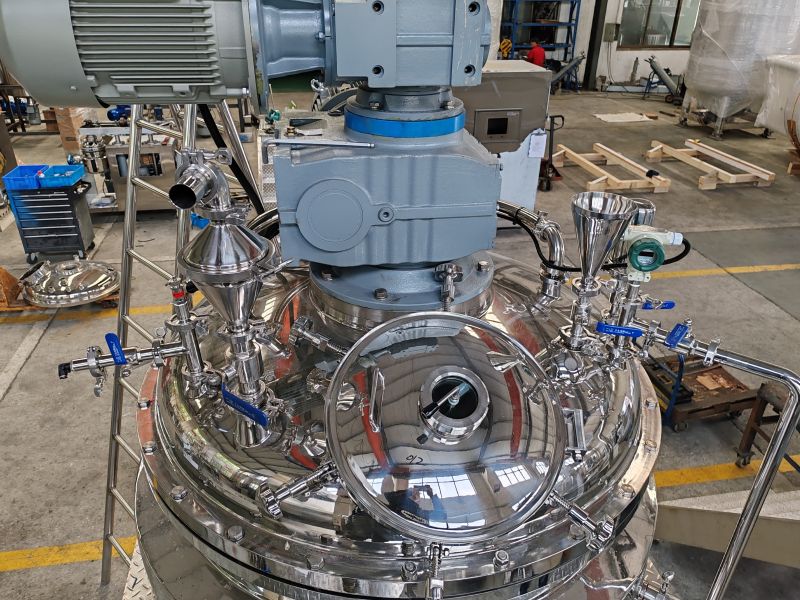

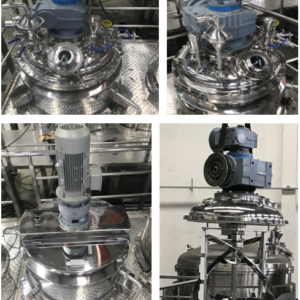

1. The Flanged Fixed SME-B 1000L Vacuum Homogenizer Emulsifier Mixer is built with a three-layer stainless steel pot body, ensuring durability and resistance to corrosion. The flanged sealed pot cover adds an extra layer of security, preventing any leakage during operation. This robust construction makes it suitable for handling a wide range of products, including cosmetics, pharmaceuticals, food, and chemical compounds.

2. One of the key features of this mixer is its two-way screw belt wall scraping stirring system, located at the top of the pot. This system ensures thorough mixing and blending of ingredients, resulting in a uniform and consistent product. Additionally, the internal circulation homogenizing system at the bottom of the pot further enhances the emulsifying and homogenizing process, creating stable and high-quality end products.

3.The Flanged Fixed SME-B 1000L Vacuum Homogenizer Emulsifier Mixer is equipped with an independent PLC control electrical cabinet, allowing for precise control and monitoring of the mixing parameters. This advanced control system enables operators to adjust settings such as mixing speed, homogenizing pressure, and temperature, ensuring optimal results for each specific product formulation.

4.In addition to its mixing capabilities, this mixer features a pneumatic discharge system, facilitating easy and efficient product transfer after the mixing process is complete. The independent platform provides a stable and secure base for the equipment, while the vacuum system ensures the removal of air and other gases from the product, resulting in improved product quality and shelf life.

5.Furthermore, the steam heating and water cooling pipeline system integrated into the Flanged Fixed SME-B 1000L Vacuum Homogenizer Emulsifier Mixer allows for precise temperature control during the mixing and homogenizing process. This feature is essential for industries that require specific temperature conditions to achieve the desired product characteristics.

Technical Parameter

| Items | Vacuum Emulsifying Mixer | |

| Model | SME-B 1000L | |

| Design Capacity | 1250L | |

| Working Capacity | 1000L | |

| Specification (L*W*H) unit(mm) | 1650*1650*2556 | |

| Homogenizer Motor | Power | 18.5KW |

| Revolution | 0-3000r(min) | |

| Stir Motor | Power | 7.5KW |

| Revolution | 0-60r(min) | |

| Heat Method | Steam heating | |

| Note: In case of inconformity of the data in the table due to technical improvement or customization, the real object shall prevail | ||

Product Details

Note: The picture is customized for reference only

SME-B 1000L Vacuum Homogenizer Emulsifying Machine

The vacuum homogenizer emulsifying mixer with helical ribbon mixing and double-way mixing system, along with wall scraping stirring, is a highly efficient and versatile mixing system

Cover Element

Control part

(PLC Control Touch screen control)

The emulsifier’s product configuration also includes Siemens Motor and Siemens converter components. These brands are well-known for their high-quality electrical and mechanical components that enhance the overall performance and longevity of the machine.

Schneider Electric is responsible for the electrical control of the emulsifier, ensuring reliable and safe operation. The Delta components further enhance the efficiency and performance of the electrical system.

Relevant Machines

We can offer machines for you as following

Reverse osmosis water purifier, vacuum homogenizing emulsifier. aseptic storage tank, drying sterilizer, ointment filling machine. conveying workbench, code printer, labeling machine, aluminum foil sealing machine, shrink film machine

Click the picture to jump to the link related to the product

- RO Water Machine

- Bottle Washing Machine

- Bottle Drying Sterilizer

- Stainless steel storage tank

- Cream & Paste Filling Machine

- Splint type sachet packing machine

- Tube Filling And Sealing Machine

- Automatic aluminum foil sealing machine

- Labelling Machine

- Automatic Capling Machine

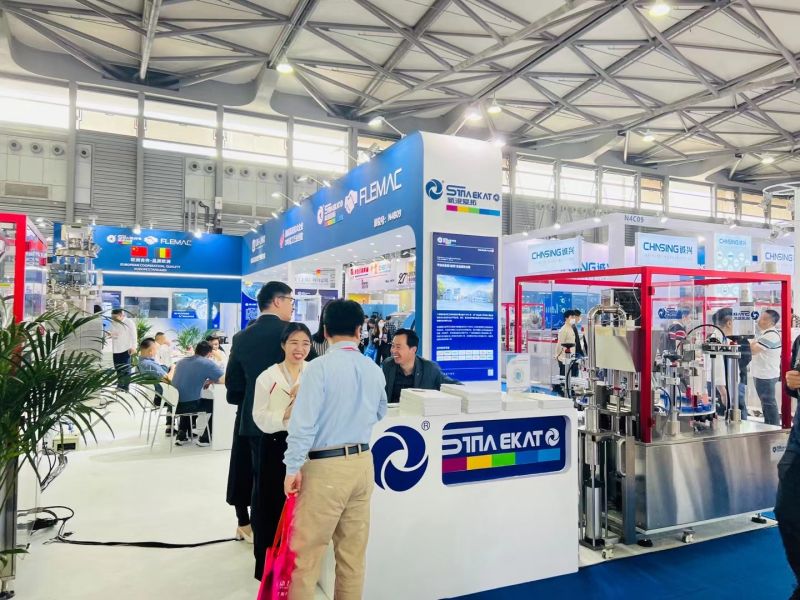

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, foodchemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

Workshop Production

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Our Project

Packing and Shipping

Exhibitions & Customers visit factory

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

.jpg)

Reviews

There are no reviews yet.