Description

Application

Cosmetics industry: The colloid mill is utilized in the production of cosmetics such as lotions, creams, and emulsions. It helps in achieving a stable and smooth texture, ensuring uniform mixing and dispersion of ingredients.

Food and beverage industry: The colloid mill is used in the production of sauces, dressings, mayonnaise, spreads, and other emulsions. It helps in achieving a smooth and uniform texture and dispersing ingredients evenly.

Pharmaceutical industry: Colloid mills are used for the dispersion and homogenization of pharmaceutical ingredients, including ointments, creams, suspensions, and oral dosage forms. The mill ensures uniform distribution of active ingredients and aids in improving product stability.

Features and Advantages

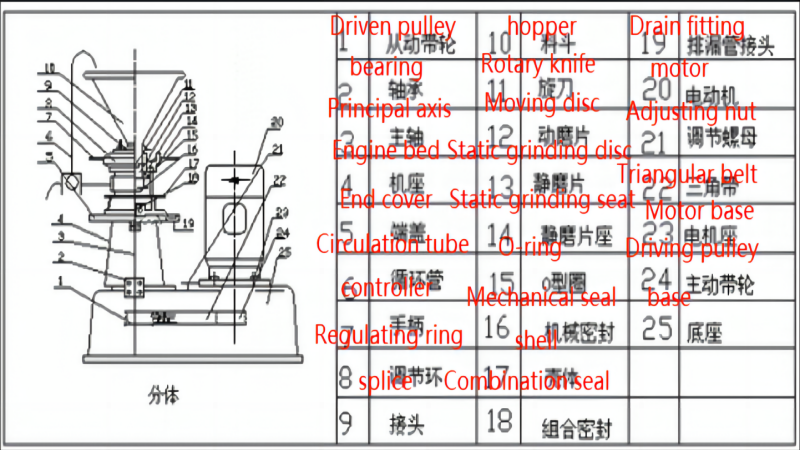

1, the work of split type colloid mill is to rely on the relative movement of the rotating teeth and the fixed teeth, the material through the gap between the fixed teeth by shear force, friction, centrifugal force and high-frequency vibration, and the purpose of crushing, emulsifying, homogenizing and dispersing.

2, grinding contact material parts are made of stainless steel materials, no pollution to medicine, food and chemical raw materials.

3, split type colloid mill motor and grinding block discrete, with good stability, easy operation, long motor service life and other characteristics, will not produce material leakage and burn the motor phenomenon.

4, the main working part is divided into rotor and stator, the adjustment ring is used for micro adjustment of the gap, and is equipped with a dial mark, easy to read, easy to control, to ensure the quality of processed products.

5, relative to the pressure homogenizer, colloid mill is first of all a centrifugal equipment

Assembly-drawing

Technical Parameter

| Model | 50 | 80 | 100 | 120 | 140 | 180 | 200 | |

| Emulsification fineness (µm) | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |

| Range of regulation | 1-0.01 | 1-0.01 | 1-0.01 | 1-0.01 | 1-0.01 | 1-0.01 | 1-0.01 | |

| yield t/h (varies according to material nature) | 0.30~1 | 0.3~1 | 0.5~2 | 0.7~3 | 1~4 | 2~7 | 3~9 | |

| Electric machine | power | 1.1 | 3 | 5.5 | 7.5 | 11 | 18.5 | 22 |

| voltage | 380/220 | 380 | 380 | 380 | 380 | 380 | 380 | |

| Rotational speed (r/min) | 1700-3500 | 1700-3500 | 1700-3500 | 1700-3500 | 2930 | 2940 | 2900 | |

| Grinding disc diameter (mm) | 50 | 80 | 100 | 120 | 140 | 180 | 200 | |

| Discharge port diameter (inch) | 5/8″ | 1″ | 1″ | 1″ | 3/2″ | 2″ | 2″ | |

| Inlet diameter (inch) | 5/4″ | 2″ | 5/2″ | 5/2″ | 5/2″ | 10/3″ | 10/3″ | |

| Cooling water pipe diameter (inch) | 1/8″ | 1/8″ | 1/4″ | 1/4″ | 1/4″ | 1/4″ | 1/4″ | |

| Overall dimension | Long (mm) | 500 | 820 | 870 | 870 | 870 | 1060 | 1070 |

| Wide (mm) | 311 | 400 | 460 | 460 | 460 | 530 | 550 | |

| High (mm) | 500 | 830 | 970 | 970 | 1040 | 1200 | 1200 | |

| Weight (kg) | 60 | 200 | 275 | 285 | 320 | 450 | 500 | |

Related products

We can offer machines for you as following :

(1)Cosmetics cream ,ointment ,skin care lotion ,toothpaste production line

From Bottle washing machine -bottle drying oven -Ro pure water equipment -mixer -filling machine -capping machine -labeling machine -heat shrink film packing machine -inkjet printer -pipe and valve etc

(2)Shampoo, liquid soap ,liquid detergent(for dish and cloth and toilet etc ) ,liquid wash production line

(3)Perfume production line

(4)And other machines ,powder machines ,lab equipment ,and some food and chemical machines

- RO Water Machine

- Bottle Washing Machine

- Bottle Drying Sterilizer

- Stainless steel storage tank

- Vacuum Homogenizer mixer

- Liquid Washing Homogenizing Mixer

- Cream & Paste Filling Machine

- Auto-Filling Machine

- Labelling Machine

- shrinking seal wrapping machine

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, food chemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

Workshop Production

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Our Project

Packing and Shipping

- Packing

Exhibitions & Customers visit factory

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

.jpg)

-300x300.jpg)

Reviews

There are no reviews yet.