Description

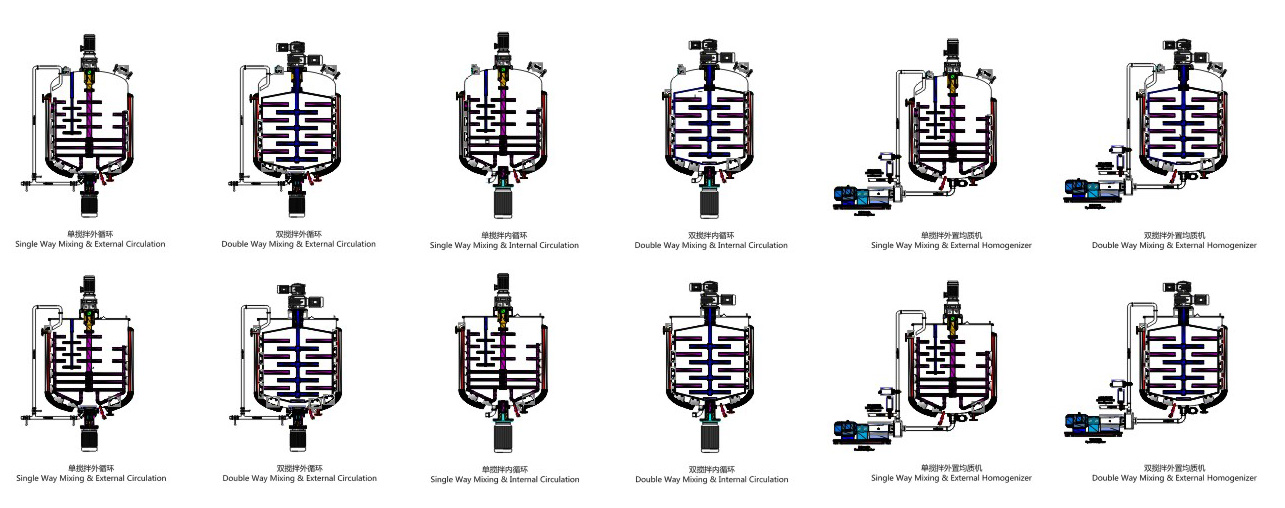

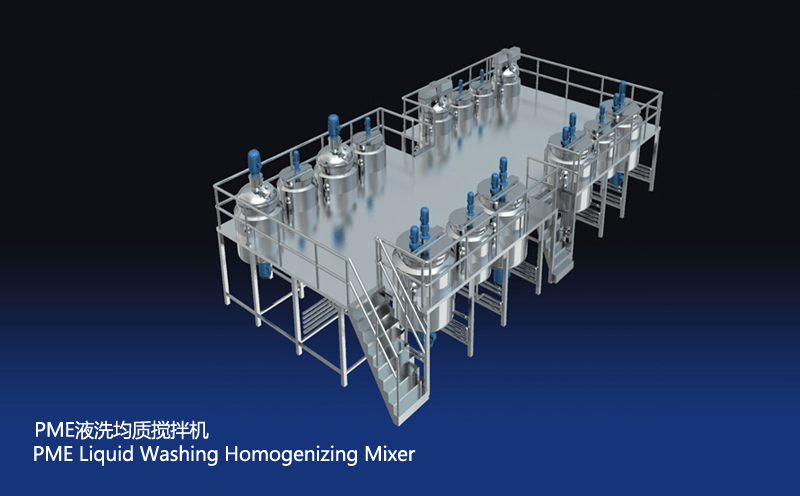

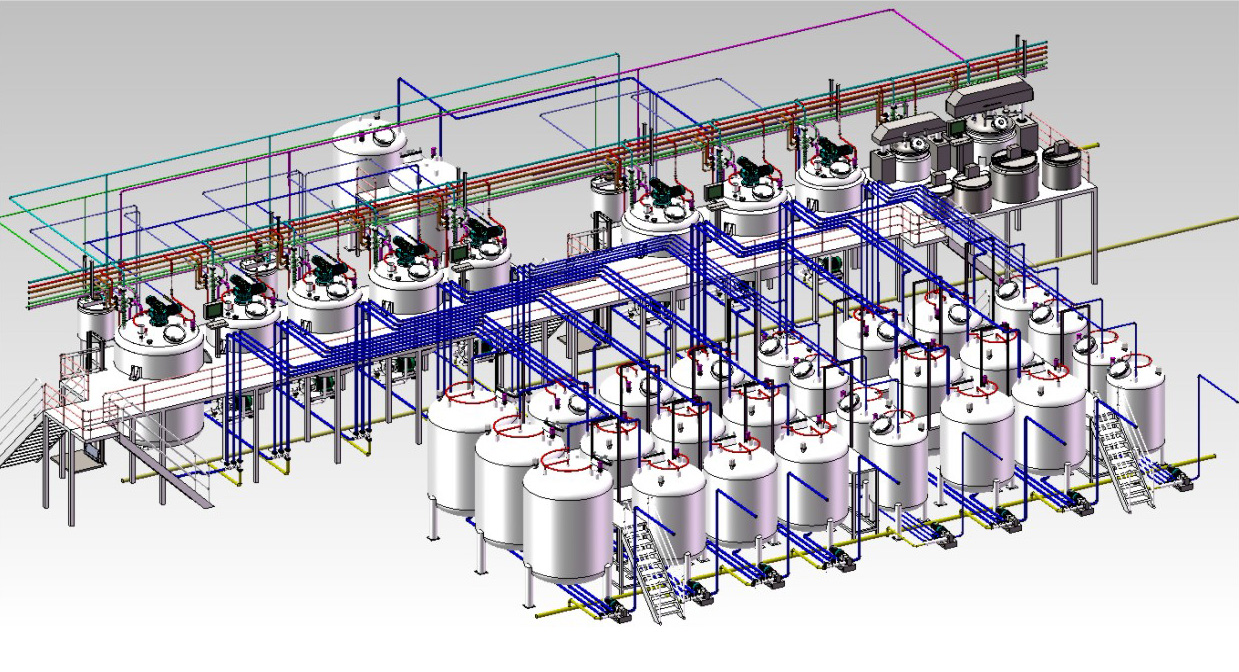

Usage This unit is available for manufacturing liquid products(such as detergent,shampoo,shower gel,etc.),it integrates mixing,homogenizing,heating,cooling,pump discharging finished products and defoaming(optional)functions.It is the ideal equipment for liquid products in domestic and international factories.

Performances and features

The all-round wall scraping mixing adopts the frequency converter for speed adjustment,so that high quality products of different processes according to customer requirements.

The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolve many indissoluble materials such as AES,AESA,LSA,etc.during the liquid detergent production process so as to save energy consumption and shorten production period.

The pot body is welded by imported three-layer stainless steel plate.The tank body and the pipes adopt mirror polishing,which fully conforms to GMP requirements.

According to customer requirement,the tank can heat and cool materials.Theheating way including steam heating and electric heating.Easy to discharge,bottom direct discharge or by transfer pump.

| Technical parameter | ||||||

| Model | Capacity | Mixing Power (kw) |

Mixing Speed (r/min) |

Homogenizing Power (kw) |

Homogenizing Speed | Heating Method |

| PME-200 | 200 | 0.75 | 0-65 | 2.2-4 | 3000 | Steam Heating or Electic Heating (optional) |

| PME-300 | 300 | 0.75 | 0-65 | 2.2-4 | 3000 | |

| PME-500 | 500 | 2.2 | 0-65 | 5.5-7.5 | 3000 | |

| PME-1000 | 1000 | 4 | 0-65 | 7.5-11 | 3000 | |

| PME-2000 | 2000 | 5.5 | 0-53 | 11-15 | 3000 | |

| PME-3000 | 3000 | 7.5 | 0-53 | 18 | 3000 | |

| PME-5000 | 5000 | 11 | 0-42 | 22 | 3000 | |

| PME-10000 | 10000 | 15 | 0-42 | 30 | 3000 | |

| Note:In case of in conform ty of the data in the table due to technical improvement or customization, the real object shall prevail | ||||||

Reviews

There are no reviews yet.