Description

Application

It is widely used in industries with high requirements for cleaning, such as daily chemical, biological fermentation, and pharmaceuticals, in order to achieve the effect of sterilizing. According to the process condition, single tank type, double tanks type. separate body type can be chosen. Smart type and manual type are also optional.

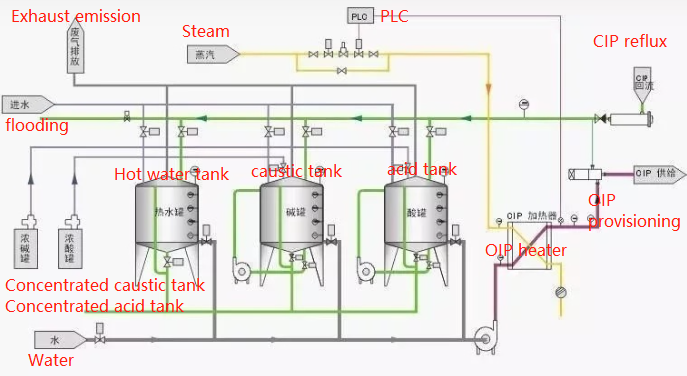

Working Principle

Through set programme (adjustable programme). CIP system makes automatically preparation clean liquid. It finishes transfer of clean liquid and whole clean process of circulation circle clean and drain and recovery via pneumatic control valve and transfer pump and loop liquid pump. Through conduct inspection instrument and PLC constituting control system reaches auto online clean.

Performances And Features

1. Economic operation, low cost, compact structure, small area, simple installation and maintenance.

2. Processed in confined equipment (tank containers and pipeline) and thus greatly reducing the chance of secondary contamination.

3. It can clean several district at the same times and clean during the production process. Thus greatly reduced the production time of the CIP cleaning.

4. It can automatically switch process parameters and adjust cleaning time, PH, temperature and other parameters. Especially the automatic CIP can automatically detect, plus liquid, emissions, display and adjust to cleaning fluid. It is more in line with sanitary requirement and production environment demand of modern large-scale fluid drugs and food processing because its reliable operation, high automation, simple operation and good cleaning effect.

5. Factory direct supply cip systems divided into one-piece type, dual tanks and multi tanks.

Technical Parameters

| Model | CIP I(Single tank type) CIP II(Double tank type) CIP III(Three Tanks type) |

|||

| Product Name | CIP Cleaning System | |||

| CIP tank type | Alcali tank,acid tank,hot water,clean water tank,water recycle tank | |||

| Cleaning recycles | Single circuit,double circuits,three circuits | |||

| Heating method | Coil pipes inside,plate heat exchanger ,tubular heat exchanger | |||

| Material | Stainless Steel 304/316 | |||

| Automatic types and charastics | Full Automatic | 1. Flow rate auto control; | ||

| 2. Temperature auto control; | ||||

| 3. Auto compensate the cip liquid level; | ||||

| 4. Auto compensate the liquid concentrate; | ||||

| 5. Cleaning liquids auto transfer; | ||||

| 6. Auto alarm | ||||

| Semi-automatic control | 1. Temperature auto control | |||

| 2. Electrical control with manual operate the other matters | ||||

| Manual control | Manual operate on the cleaning process | |||

| Application | Cosmetics food pharmaceutical industry | |||

Relevant Machines

- Bottle Washing Machine

- Tube Filling And Sealing Machine

- RO Water Machine

- Vacuum Homogenizer mixer

- Liquid washing machine

- TVF-QZ-Six-head-Automatic-Liquid-Filling-Machine

- Labelling Machine

- shrinking seal wrapping machine

Packing & Delivery

Packing details: The normal package is wooden box (Size: L*W*H). If machine is delivery to European countries, the wooden box will be fumigated. If container is too tighter, we will use PE film for packing or pack it according to customer’s special request.

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, foodchemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Contact Person

Ms Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

Reviews

There are no reviews yet.