Description

Application

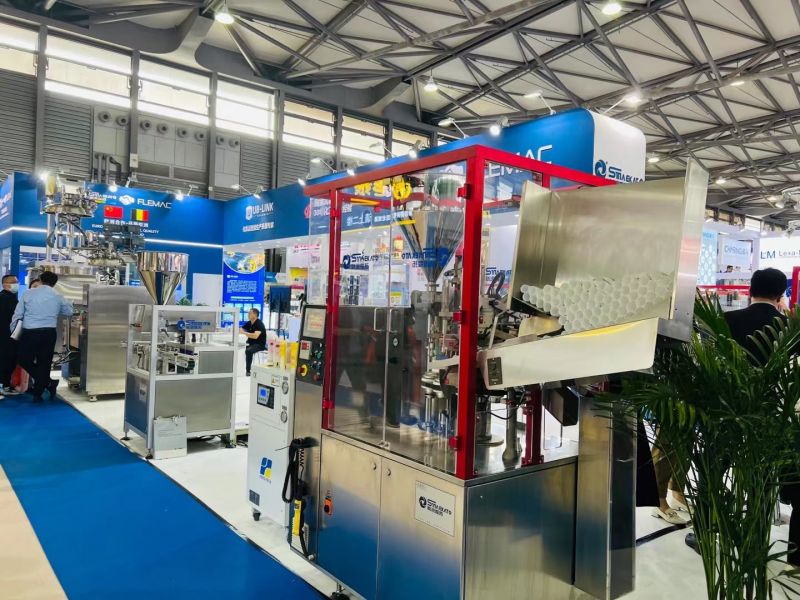

The automatic mascara filling and capping machine is used in the cosmetic industry for filling and capping mascara containers.

Performances And Features

1, the photoelectric sensor detects whether the empty bottle exists on the main turntable of the work, and sends the detection signal to the control computer to control the bottle plug, screw the cap, no bottle do not plug, do not screw the cap.

3, using piston filling, filling accuracy. the use of vibration capping device to manage the inner plug, artificial hair brush. 5, the use of manipulator automatic insertion, high pass rate.

4, the use of manipulator automatic pressure cover, with guiding mechanism, accurate positioning, high efficiency. , the use of servo motor screw cap, torsion can be adjusted, no damage to the cap. . The pneumatic structure is used to push out the filled bottle and automatically fall into the guide groove.

5.High efficiency: Automatic mascara filling and capping machines are designed to deliver high-speed and accurate filling and capping operations. They can be customized to meet different production requirements and run for long hours without breaking down.

6.User-friendly design: The machines are designed with a user-friendly interface that makes operation easy and straightforward. They can be easily adjusted to suit the different sizes and shapes of containers for mascara filling.

7.Precision filling: The filling process is automated, which means the volume of mascara dispensed into each container is accurately controlled to ensure consistent fill levels.

8.Accurate capping: The capping mechanism is designed to ensure the containers are tightly sealed with no leaks or spills.

9.Easy maintenance: The machine’s design allows for easy maintenance, cleaning, and sanitization, which ensures that it delivers consistent results over extended periods.

10.Cost-effective: With the automation of filling and capping, the machine reduces labor and operational costs. It also reduces the likelihood of errors, which minimizes raw material losses and product wastage.

11.Safety: The machine is designed with safety features that protect operators and ensure a safe working environment. Some features include safety doors, emergency stop buttons, and warning signals.

Technical Parameter

| Model | SM—400 | Power Supply | 3/N/PE AC380V 50HZ 5.5KVA |

| Weight | 1200kg | Max Current | 20A |

| Tube Size | R 15-33mm L 70- 123mm |

External Dimension | (L x W x H)mm |

| Speed | 40t/m | Air Consumption | 280L/min |

Product Details

1.Capacity: The machine’s capacity depends on the specific model, but typically it can fill and cap 30 to 80 containers per minute.

2.Filling accuracy: The automatic mascara filling and capping machine is designed to ensure that the product is accurately filled to the desired level. It uses various sensors and mechanisms to monitor product flow and level and adjusts the filling accordingly.

3.Capping mechanism: The machine uses a capping mechanism that ensures the mascara containers are tightly sealed. The capping mechanism includes a cap feeder, which feeds each cap to the container, and a cap presser, which applies pressure to tighten the cap.

4.Conveyor belt system: The machine comes with a conveyor belt system that transports the mascara containers through the filling and capping process. The conveyor belt system is adjustable and can handle various container sizes and shapes.

5.Control panel: The automatic mascara filling and capping machine comes with a user-friendly control panel that allows the operator to control the filling and capping process. The control panel includes a touch screen interface that displays important information, such as production speed and filling accuracy.

6.Material construction: The machine is made with high-quality materials, including stainless steel and aluminum, which ensure its durability and resistance to corrosion.

7.Safety features: The machine has various safety features, including emergency stop buttons, safety sensors, and safety guards that prevent accidents and protect the operator.

Main configuration List:

| No | Name | Original |

| 1 | PLC | SIEMENS |

| 2 | Touch screen | SIEMENS |

| 3 | Servo motor(Filling) | MITSUBISHI |

| 4 | Conveyor belt motor | JSCC |

| 5 | Alternating current contractor | Schneider |

| 6 | Emergency stop | Schneider |

| 7 | Power Switch | Schneider |

| 8 | Buzzer | Schneider |

| 9 | Converter | MITSUBISHI |

| 10 | Filling nozzle cylinder | AirTAC |

| 11 | Rotary valve cylinder | AirTAC |

| 12 | Blocking bottle cylinder | AirTAC |

| 13 | Clamping bottle cylinder | AirTAC |

| 14 | Detection of photoelectric | OMEON |

| 15 | proximity switch | OMEON |

| 16 | Solenoid valve | AirTAC |

| 17 | Filter | AirTAC |

Relevant Machines

We can offer machines for you as following

Reverse osmosis water purifier, vacuum homogenizing emulsifier. aseptic storage tank, drying sterilizer, ointment filling machine. conveying workbench, code printer, labeling machine, aluminum foil sealing machine, shrink film machine

Click the picture to jump to the link related to the product

- RO Water Machine

- Bottle Washing Machine

- Bottle Drying Sterilizer

- Stainless steel storage tank

- Automatic aluminum foil sealing machine

- Labelling Machine

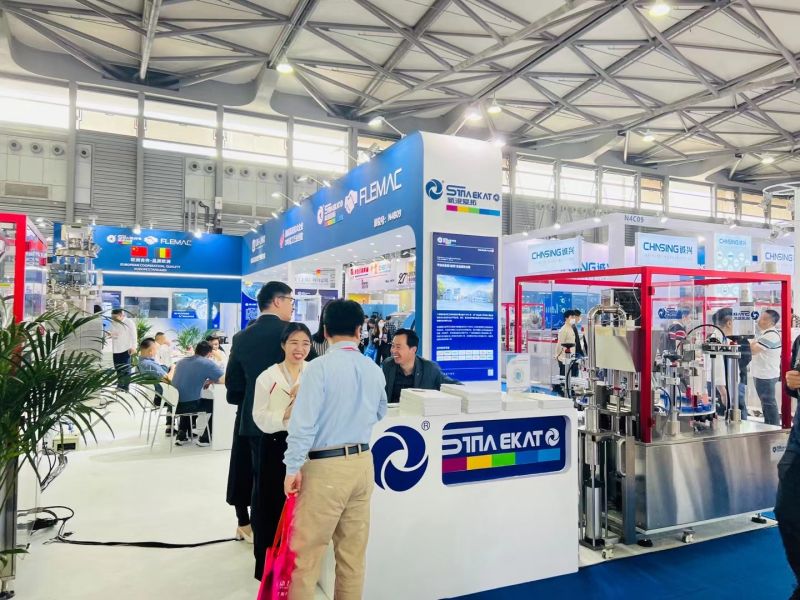

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, foodchemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

Filling Workshop Production

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Our Project

Packing and Shipping

Exhibitions & Customers visit factory

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

.jpg)

Reviews

There are no reviews yet.