Description

Application

1.Cosmetic Industry: The mixer is used for the production of cosmetic products like creams, lotions, serums, and emulsions. It ensures uniform blending of various ingredients, such as oils, water, pigments, and thickeners, resulting in stable and smooth textures.

2.Pharmaceutical Industry: It is used for the production of creams, ointments, gels, and lotions, incorporating active ingredients into a base. It can also be used for the emulsification and dispersion of drug substances.

3.Food Industry: In the food industry, the mixer is utilized for the production of sauces, dressings, mayonnaise, and other emulsified food products. It helps in achieving the desired texture and consistency by effectively blending and emulsifying ingredients.

4.Chemical Industry: This mixer finds application in the production of various chemical compounds, such as paints, adhesives, resins, and coatings.

Performance And Features

1.The main pot lid is integrated with the pot body and cannot be opened, it is connected by a flange.

2.The main pot The oil pot and the water pot are made of three-layer stainless steel welding, the inner layer in direct contact with the material is made of imported SUS316L stainless steel, the middle jacket layer and the external thermal insulation layer are made of 304 stainless steel, and the tank body and pipeline are mirror-polished or matte, which fully meets the GMP requirements.

3.The material heating method can choose electric heating or steam heating, pay attention to the pressure of steam heating can not exceed the factory preset pressure value of 2kg, the use of electric heating needs to ensure that the jacket is heated by the medium, otherwise dry burning will damage the heating rod

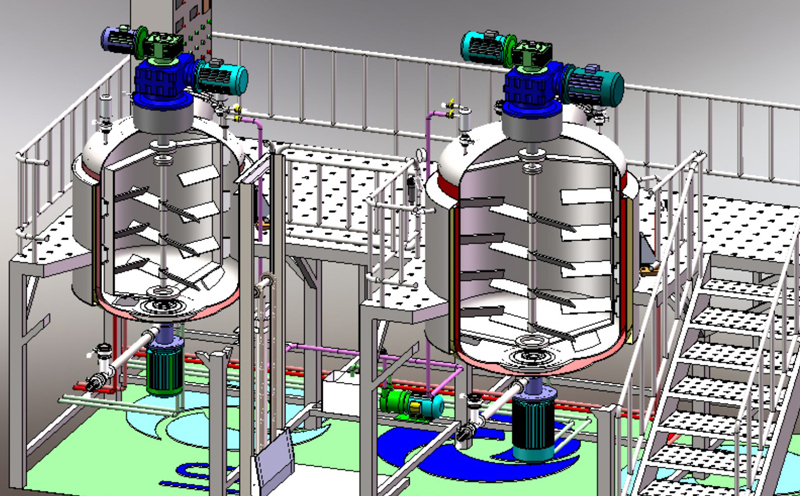

4.The mixing system of the machine can provide one-way mixing scraping wall mixing and two-way mixing scraping wall mixing methods according to the actual production needs of customers, and there are many options for mixing pulp forms, such as spiral belt mixing, frame mixing, etc. The motor brand of the mixing system is Siemens of Germany and adopts German Burgmann mechanical seal and Japanese NSK bearing Variable stirring speed: 0~63r/min, and the speed is adjusted by the Siemens frequency converter in the power distribution cabinet

5.The homogenization method of the machine can choose the bottom internal circulation homogenization or the external circulation system homogenization, the bottom homogenization homogenization motor is German Siemens, through the Siemens frequency converter of the distribution box to adjust the speed, the speed is adjustable: 0~3600r/min

6.The oil pot and water pot adopt a top dispersion system, its motor is a Siemens motor, through the Siemens frequency converter in the distribution box to adjust the speed, the mechanical seal adopts German Burgmann, and the opening method is generally half open

7.The distribution box is made of 304 stainless steel, its PLC and inverter adopt German Siemens, the electrical components adopt German Schneider, the instrument adopts Omron, and the distribution box can choose PLC touch screen control (touch screen adopts German Siemens) or electronic control button control

8.7. The scraper type agitator mixing adopts the frequency converter for speed adjustment , so that high quality products of different processes according to customer requirements.

9.Oil pot and water pot as pre-heating and pre-mixing,it is necessary for batch production,it efficiently save the preparation time.

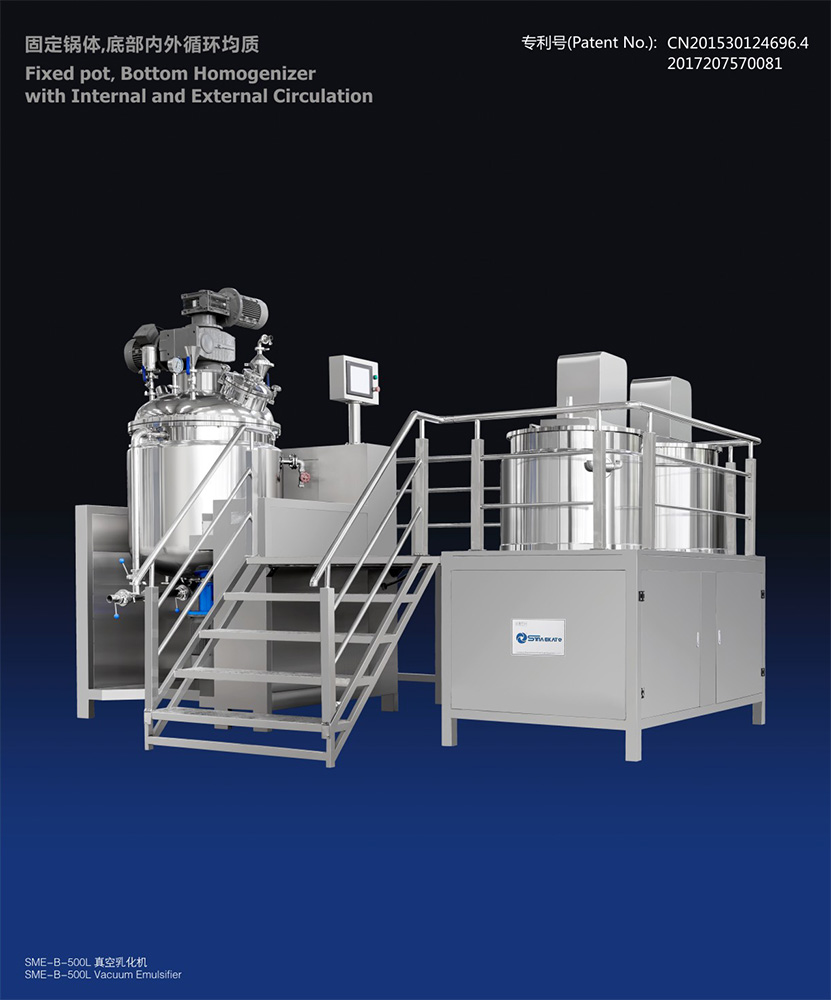

| SME-B Vacuum Emulsifying Mixer Fixed pot, Bottom Homogenizer with Internal and External Circulation |

|||||||||||

| Technical parameter | |||||||||||

| Model | Capacity | Homogenizer Motor | Stir Motor | Dimension | Total Power(KW) | Limit vacuum(Mpa) | |||||

| KW | r/min | KW | r/min | Length(mm) | Width(mm) | Height (mm) | Steam heating | Electric heating | |||

| SME-B100 | 100L | 2.8-4 | 1440/2880 | 1.5 | 0-63 | 2750 | 2700 | 2250 | 13 | 32 | -0.09 |

| SME-B200 | 200L | 6.5-8 | 1440/2880 | 2.2 | 0-63 | 3100 | 3000 | 2500 | 15 | 45 | -0.09 |

| SME-B300 | 300L | 6.5-8 | 1440/2880 | 2.2 | 0-63 | 3500 | 3350 | 2650 | 18 | 49 | -0.085 |

| SME-B500 | 500L | 6.5-8 | 1440/2880 | 4 | 0-63 | 3850 | 3600 | 2750 | 22 | 61 | -0.08 |

| SME – B1000 | 1000L | 9-11 | 1440/2880 | 5.5 | 0-63 | 4200 | 3850 | 3300 | 28 | 88 | -0.08 |

| SME-B2000 | 2000L | 11-14 | 1440/2880 | 5.5 | 0-63 | 4500 | 4050 | 3800 | 34 | – | -0.08 |

| SME-B3000 | 3000L | 15-18 | 1440/2880 | 7.5 | 0-63 | 4800 | 4300 | 4100 | 40 | – | -0.08 |

| Note: In case of inconformity of the data in the table due to technical improvement or customization, the real object shall prevail. | |||||||||||

Advantages

1.Design: we have many design of vacuum emulsifying pot design patents, generous beauty of its appearance, internal mixing of advanced design, reasonable use with no dead Angle scraping the walls combined frame of mixing and ribbon mixing efficiency; Homogeneous machine adopt the Germany technology homogeneous structure, using imported double mechanical seal, shear emulsifying effect, good sealing, The main pot pot can choose single cylinder or twin lift according to customer requirements, cleaning and maintenance is convenient; The pot body can dump out the material, the material with high efficiency;

2.Material: we imported from Japan and Finland’s board, quality assured.

3.Welding: Barrel body USES the automatic welding technology of weld a laymen, adopts the seamless stir welding to avoid cleaning blind Angle.

4.Polishing: mirror polished on both inside and outside of tank, in full compliance with GMP requirements.

5.Vacuum:high vacuum degree highest can reach -0.09 Mpa, deaeration effect is better.

6.Electric appliance: 80% of the main parts of our products are provided by world’s famous suppliers, such as Siemens, Mitsubishi, Schneider configuration to ensure that the whole machine control is more stable, fully meet international standards.

Related products

We can offer machines for you as following :

(1)Cosmetics cream ,ointment ,skin care lotion ,toothpaste production line

From Bottle washing machine -bottle drying oven -Ro pure water equipment -mixer -filling machine -capping machine -labeling machine -heat shrink film packing machine -inkjet printer -pipe and valve etc

(2)Shampoo,liquid saop ,liquid detergent(for dish and cloth and toilet etc ) ,liquid wash production line

(3)Perfume production line

(4)And other machines ,powder machines ,lab equipment ,and some food and chemical machines

- RO Water Machine

- Bottle Washing Machine

- Bottle Drying Sterilizer

- Vacuum Homogenizer mixer

- Liquid Washing Homogenizing Mixer

- Stainless steel storage tank

- TVF-QZ-Six-head-Automatic-Liquid-Filling-Machine

- Automatic aluminum foil sealing machine

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, foodchemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

Workshop Production

Our Advantage

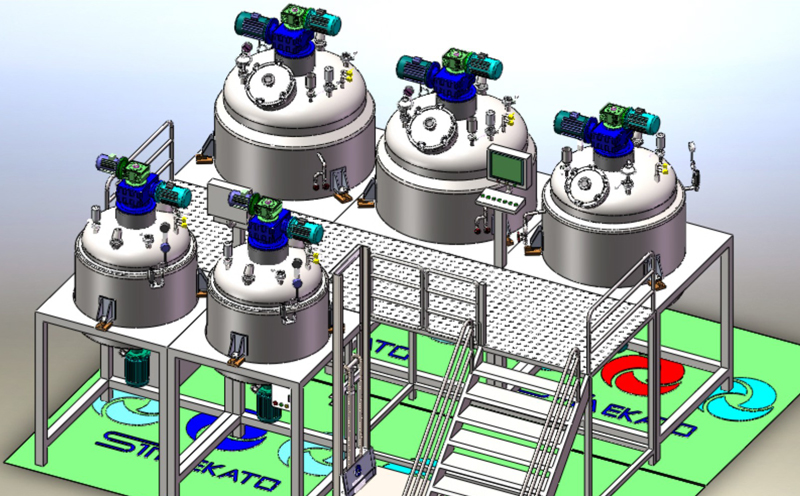

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Our Project

Packing and Shipping

- Packing

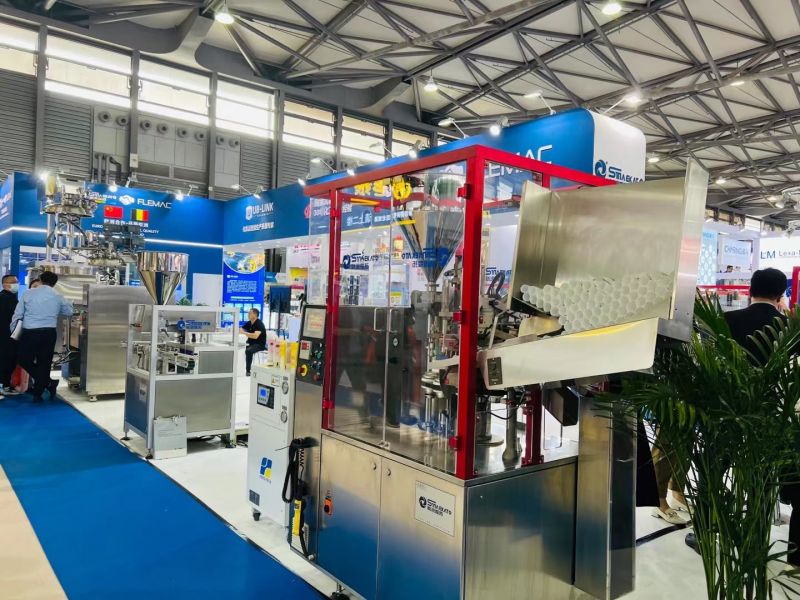

Exhibitions & Customers visit factory

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

Reviews

There are no reviews yet.