Description

Application

Performances And Features

1. High speed rotor endows the material with high centrifugal speed and great centrifugal force. When slowing down instantaneously, the material suffers the associative action of cavitation, detonation, shearing and grinding. Meanwhile, the material is imbibed from upside of the homogenizer and erupted from the sideward plug hole. By the combined action of the stirrer along the vessel wall, granule spreads homogeneously and uniformly and the degree of uniformity shall come up to more than 99%.

Slow speed blade type blending and high speed homogenizing systems are provided with frequency conversion control.

2. Very small aperture between stator and rotor shall assure the effect of grinding, shearing, mixing and emulsifying of the material and avoid colliding and friction during the rotor rotates with high speed.

3.The tank body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mirror polishing or matte finish , which fully conforms to GMP requirements.

4.The machine equipped with CIP, which can convinient user’s own CIF system to clean the machine.

Technical Parameter

| Model | Capacity | Homogenizer Motor | Stir Motor | Dimension | Total Power | Limit vacuum(Mpa) | |||||

| KW | r/min | KW | r/min | Length(mm) | Width(mm) | Height(mm) | Steam heating | Electric heating | |||

| SME-C5 | 5L | 0.37 | 3000 | 0.18 | 63 | 1260 | 540 | 1600/1850 | 2 | 5 | -0.09 |

| SME-C10 | 10L | 0.75 | 3000 | 0.37 | 63 | 1300 | 580 | 1600/1950 | 3 | 6 | -0.09 |

| SME-C50 | 50L | 3 | 3000 | 1.1 | 63 | 2600 | 2250 | 1950/2700 | 9 | 18 | -0.09 |

| SME-C100 | 100L | 4 | 3000 | 1.5 | 63 | 2750 | 2380 | 2100/2950 | 13 | 32 | -0.09 |

| SME-C200 | 200L | 5.5 | 3000 | 2.2 | 63 | 2750 | 2750 | 2350/3350 | 15 | 45 | -0.09 |

| SME-C300 | 300L | 7.5 | 3000 | 2.2 | 63 | 2900 | 2850 | 2450/3500 | 18 | 49 | -0.085 |

| SME-C500 | 500L | 11 | 3000 | 4 | 63 | 3650 | 3300 | 2850/4000 | 24 | 63 | -0.08 |

| SME-C1000 | 1000L | 15 | 3000 | 5.5 | 63 | 4200 | 3650 | 3300/4800 | 30 | 90 | -0.08 |

| SME-C2000 | 2000L | 15 | 3000 | 7.5 | 63 | 4850 | 4300 | 3800/5400 | 40 | _ | -0.08 |

| Note: In case of inconformity of the data in the table due to technical improvement or customization,the real object shall prevail | |||||||||||

Product Details

The homogenizing stirring system of SME-C bidirectional stirring vacuum emulsifier iscomposed of high-speed homogenizer shear, center stirring paddle and scrapingstirring frame. High shear homogenizer can quickly refine the material. When it comesto sticky products, the stirring function of the single homogenizer is not sosignificant, but with the center mixing and box scraping of two-way mixing, the high-speed shear of the homogenizer can be faster and more efficient, and the full volumeof materials can be quickly stirred without dead corners.

Cover parts(pressure meter, sight glass lamp, suck material inlet, manhole, etc)

Shape of the Blender Blades: Two -way mixing with frame scraping wall Button Controlled: Each button has it own function, adjust mixing speed, etc.PLC control electric cabinet(clear line layout, hiperformance)

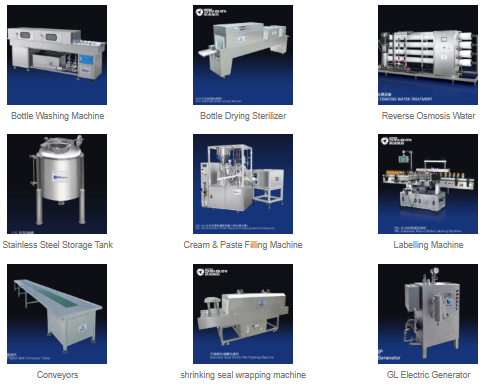

Relevant Machines

Company Profile

With the solid backing of jiangsu Province gaoyou city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national lightindustry and daily chemicals research institute, and regarding senior engineers and experts as thetechnological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer ofvarious types of cosmetic machinery and equjpment and has become a brand enterprise in the dailychemical machinery industry. The products are applied in such industries as. cosmetics, medicine, foodchemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, usA JB, etc

Workshop Production

Packing and shipping

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

Reviews

There are no reviews yet.