Description

Application

1.Cosmetics and personal care: Filling and sealing of lotions, creams, shampoos, and other beauty and personal care products.

2.Pharmaceuticals: Filling and sealing of ointments, creams, gels, and other medicinal products.

3.Food and beverage: Filling and sealing of sauces, condiments, pastes, and other food products in tubes.

Mechanical operation procedure

The ST60 is operated by only one person who has to place the empty tubes into the tube store feeder, standard store feeder included in the machine.

THE MACHINE AUTOMATICALLY CARRIES OUT THE FOLLOWING OPERATION:

-Tube transfer into the tube-holder,

-Automatic orientation according to the spot,

-Tube filling,

-Counting of filled tubes,

-Tube sealing,

-Marking of a code on the sealing,

-Ejection of the filled and sealed tubes.

Features and Advantages Mechanical operation procedure

The ST-60 Auto Tube Filling and Sealing machine is a high-quality, user-friendly, and safe machine that follows the EU standard and has “CE” support. This machine is designed with the priority of ensuring the safety of workers while providing efficient and reliable tube filling and sealing operations.

One of the key features of the ST-60 Auto Tube Filling and Sealing machine is its motor, which is equipped with a torque clutch from Italy. This feature effectively protects the machine from crashes and abnormal operations that could potentially harm workers. The Italian torque clutch is designed to sense and control the system in case of any abnormal operation or if a worker’s hand is detected inside the machine, ensuring the safety of the workers at all times.

In addition to the safety features, the machine also has a Japan safety operation handle, which is a user-friendly alternative to a simple button. This handle ensures that the operation of the machine is safe and easy for the workers, further emphasizing the focus on user-friendly design and safety measures.

The configuration of the ST-60 Auto Tube Filling and Sealing machine is designed to provide efficient and reliable tube filling and sealing operations. The machine is capable of handling a wide range of tube sizes and materials, making it suitable for various production needs. The filling process is precise and accurate, ensuring that each tube is filled with the correct amount of product. The sealing process is also efficient, producing secure and reliable seals on each tube.

Furthermore, the machine is designed to be easy to operate and maintain. The intuitive controls and user-friendly design make it simple for workers to operate the machine, reducing the risk of errors and ensuring smooth production processes. Additionally, the machine is constructed with high-quality materials and components, ensuring its durability and reliability in long-term use

Technical Parameter

| Model | ST-60 | |

| Hopper capacity | 45L | |

| Air pressure | 0.5-0.7 MPa | |

| Voltage | 380V /50Hz 3Phase 5.5 KW | |

| Filling volume | Selectable (2-20ml;5-50ml; 10-100ml; 30-220ml; 50-400ml) | |

| Filling speed | 60Pcs/min (Depend on tube size and viscidity of filling product) |

|

| Filling Precision | ≤±1% | |

| Tube diameter | DN 16-50mm (Max DN 55mm) (By changing different molds or cylinder for holding tubes |

|

| Tube length | Max 200mm-210mm | |

| Dimension(L*W*H) unit(mm) | 2200*850*2100 | |

| Note: in case of inconformity of the data in the table due to technical improvement or customization, the real object shall prevail. |

||

Product And Details

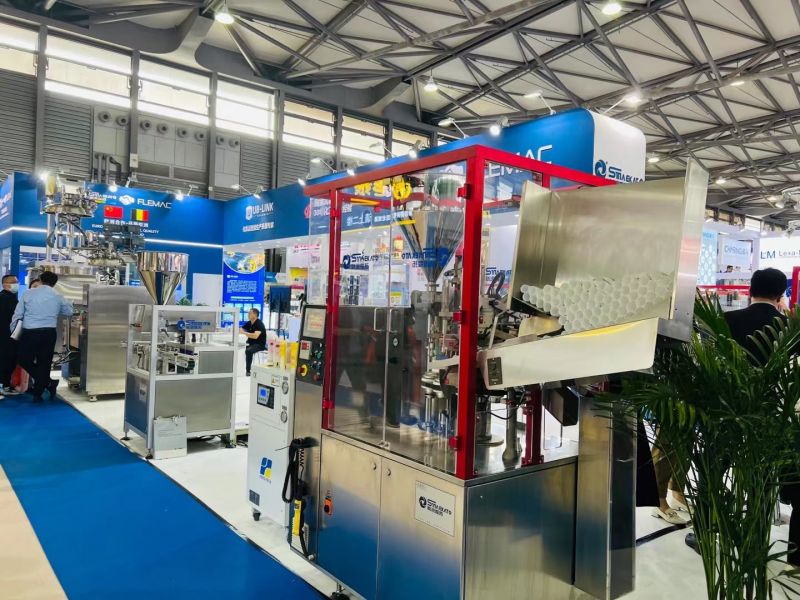

Complete machine display

Real machine operation demonstration

Related products

We can offer machines for you as following :

(1)Cosmetics cream ,ointment ,skin care lotion ,toothpaste production line

From Bottle washing machine -bottle drying oven -Ro pure water equipment -mixer -filling machine -capping machine -labeling machine -heat shrink film packing machine -inkjet printer -pipe and valve etc

(2)Shampoo, liquid soap ,liquid detergent(for dish and cloth and toilet etc ) ,liquid wash production line

(3)Perfume production line

(4)And other machines ,powder machines ,lab equipment ,and some food and chemical machines

- RO Water Machine

- Bottle Washing Machine

- Bottle Drying Sterilizer

- Stainless steel storage tank

- Cream & Paste Filling Machine

- Labelling Machine

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, food chemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

Workshop Production

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Our Project

Packing and Shipping

- Packing

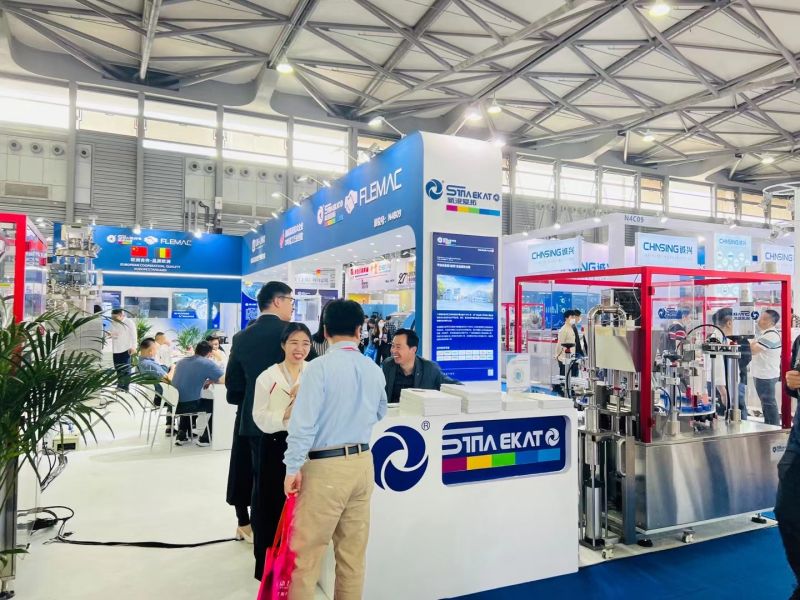

Exhibitions & Customers visit factory

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

- SME-B-4000L Upper operating part

- SME-B-4000L lower executive part

.jpg)

Reviews

There are no reviews yet.