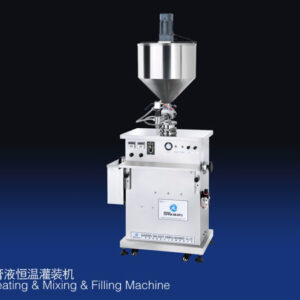

Description

Application

Mainly used for medicine (gynecology drug, erythromycin ointment, antifreeze cream, etc.), and (cosmetics, toothpaste, Emollient Cream, lipstick, shoe polish, etc.), food (fermented flour paste, tomato sauce, butter, etc.), chemicals (glass glue, sealant, white latex, ink, etc. ), lubricants, pesticides and special industry paste filling.

Performances And Features

1.The machine is made of imported mechanical parts, pistons, cylinders, stainless steel and PTFE.

The aluminum prominent imported parts and outstanding mechanical design ensure its leading position among other similar machines in China.

2.The machine is light and convenient with brand new horizontal design and automatic material drawing, removing the trouble of frequent feeding of the vertical material hopper.

3.The material cylinder and tee parts adopt handcuffs type connection, which can be conveniently disassembled and assembled without the need of using any special tools Therefore, the cleaning is very convenient.

4.Manual and automatic mutual switching function. When the machine is under the “automatic” status, the machine will automatically carry out continuous filling according to the set speed. When the machine is under the “manual” status, the operator steps on the pedal to realize the filling. If the pedal is always stepped on without releasing, the machine will change into the automatic continuous filling status.

5.The material cylinder and tee parts adopt handcuffs type connection, which can be conveniently disassembled and assembled without the need of using any special tools Therefore, the cleaning is very convenient.

6.Leakage proof filling system. During the filling, the cylinder makes upward and downward movements to drive the closure head. When the cylinder moves downwards, the closure head will move downwards, the valve will be opened and the system starts to fill the materials. When the cylinder moves upwards, the closure head will move upwards, the valve will be closed and the filling will be stopped, so that leakage and wire drawing are prevented.

Product Details

| Name | TVF Horizontal Pneumatic Ointment and Liquid Filling Machine |

| Model | TVF |

| Article | Liquid or paste |

| Volume | 500-5000ml |

| Filling | Piston pump |

| Precision | ±0.5% |

| Pneumatic | 0.6-0.8Mpa |

| Caliber | ≥5mm |

| Capacity | 0-12 times/min |

| G.W. | 55Kg. |

| Dimension | L1500*W530*H750mm |

Technical Parameter

Model filling volume Filling Speed Air Supply

TVF-5 5-60ml 0-45bot/min 0.2-0.6Mpa

TVF-10 10-120ml 0-35bot/min 0.2-0.6Mpa

TVF-25 25-250ml 0-30bot/min 0.2-0.6Mpa

TVF-50 50-500ml 0-30bot/min 0.2-0.6Mpa

TVF-100 100-1000ml 0-25bot/min 0.2-0.6Mpa

TVF-250 250-2500ml 0-18bot/min 0.2-0.6Mpa

TVF-500 500-5000ml 0-12bot/min 0.2-0.6Mpa

Note: Filling precision ±1%. In case of inconformity of the data in the table due to technical improvement or customization, the real object shall prevail

Relevant Machines

- RO Water Machine

- Bottle Washing Machine

- Bottle Drying Sterilizer

- Stainless steel storage tank

- Vacuum Homogenizer mixer

- Liquid Washing Homogenizing Mixer

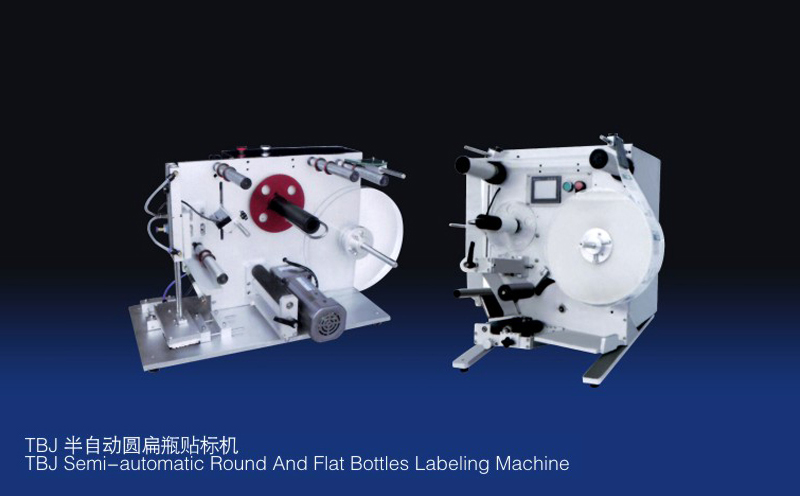

- Semi-auto labeling machine

- shrinking seal wrapping machine

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, foodchemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Our Project

Packing and Shipping

Exhibitions & Customers visit factory

Cooperative Customers

Material Certificate

Contact Person

Mrs Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

Reviews

There are no reviews yet.