Description

Application:

The six heads automatic liquid filling machine is a versatile tool that finds widespread application in the cosmetics industry.

It is used for automatic filling of various liquids into bottles. Such as shampoo, laundry detergent, shower gel, detergent,tomato sauce, sauces, lubricants,cooking oil, etc. It is suitable for filling in large quantities of factories, and can be connected to the production line before and after. It can be used together with the capping machine, capping machine, labeling machine and inkjet printer.

Performance And Features

- Equipped with a bottle mouth localizer to make the machine suitable for different shapes of bottles including irregular bottles

- “No drip” filling nozzle can assure that dripping and stringing will not happen. 3. This machine has functions of “no bottle no fill”, “malfunction check and malfunction scan automatically”, “security alarm system for abnormal liquid level”. 4. The parts are connected with clamps, which makes the machine easy and quick to disassemble & assemble and clean.

- The series of machine has compact, reasonable configuration and nice, simple appearance.

- Filling mouth with anti-drip function can be changed to lift for high foam products.

- Material feeding device control box on the feeding, so that material is always kept at a certain range to ensure the accuracy of filling volume.

- Rapid adjustment to achieve the overall filling volume, with counter display; the amount of each filling head can be individually fine-tuned, convenient.

- With PLC programming control, touch-type man-machine interface, convenient parameter setting. Fault self-diagnosis function, clear failure display. 10. Filling head is an option, easy maintenance without affecting the other single head when filling.

Technical Parameters

| Specification | TVF-QZ-6 Heads Filling Machine |

| Air pressure | 0.5-0.7 Mpa |

| Filling accuracy | ±1% |

| Voltage | 380V 220V other voltages can be customzied |

| Capacity | 500-1000ps/h,1000-3000ps/h |

| Filling speed | 40 bottles/min |

| Weight | 1000 Kg |

| Filling products | Bottom discharge |

| Filling nozzles | single head,2/4/8 heads can be customized |

Product Details

1.Stainless steel Hopper

The hopper is made of imported stainless steel material, and the inner surface of the hopper is mirror-polished

2.Filling Nozzle

Six heads fiiling nozzoles which arein contact with the materials, adoptsthe SUS.316 stainless steel,preventing the viscosity and solidfrom dropping and withdrawing.

3.Conveyor belt

The conveyor blet has sleek and smooth interface, strongly anti-oil, anti-corrosion, anti-static, in addition to conveying glass bottle, but conveying PET bottles

4. This machine adopts PLC microcomputer programmable control, set optical, electromechanical, sensing, pneumatic execution in one.

5.The piston stroke is driven by servo motor, the stroke positioning is accurate, and the filling speed is set fast and slow.When the filling is close to the mouth of the bottle, the speed pressure is reduced to prevent the liquid from spilling due to the large impact.

6.The machine has high degree of automation and convenient adjustment. When changing specifications or revising measurement, it only needs to be adjusted on the display screen to meet the requirements.

Related products

We can offer machines for you as following :

(1)Cosmetics cream ,ointment ,skin care lotion ,toothpaste production line

From Bottle washing machine -bottle drying oven -Ro pure water equipment -mixer -filling machine -capping machine -labeling machine -heat shrink film packing machine -inkjet printer -pipe and valve etc

(2)Shampoo,liquid saop ,liquid detergent(for dish and cloth and toilet etc ) ,liquid wash production line

(3)Perfume production line

(4)And other machines ,powder machines ,lab equipment ,and some food and chemical machines

- RO Water Machine

- Bottle Washing Machine

- Feeder machine

- Liquid Washing Homogenizing Mixer

- Bottle Drying Sterilizer

- Automatic aluminum foil sealing machine

- Labelling Machine

- shrinking seal wrapping machine

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, foodchemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

Workshop Production

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Our Project

Packing and Shipping

- Packing

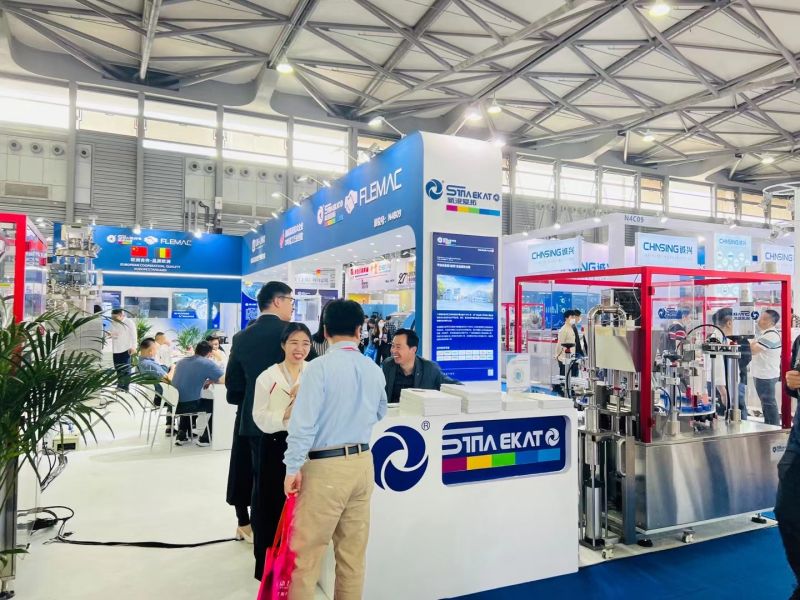

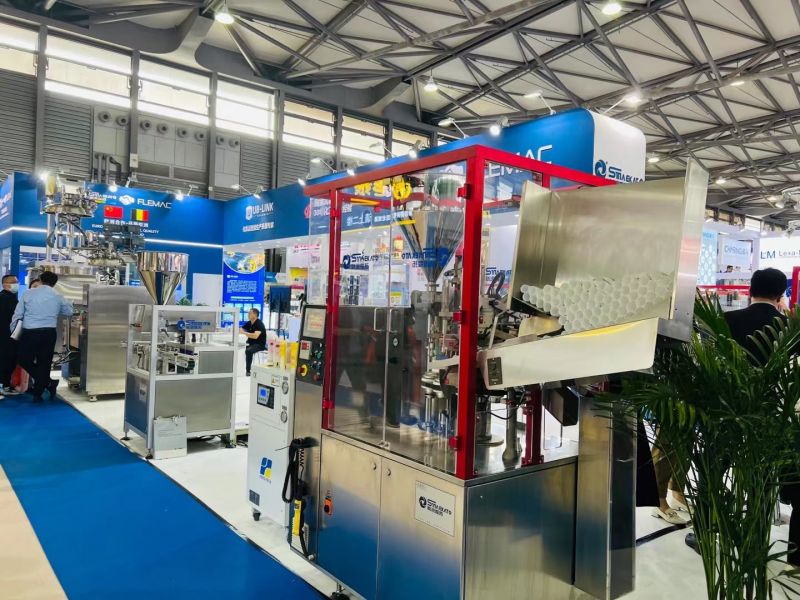

Exhibitions & Customers visit factory

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

Reviews

There are no reviews yet.