Description

Application

Suitable for a variety of cosmetics, powder, eye shadow and other cosmetics … powder processing and manufacturing.

Performances And Features

3.Suitable for a variety of cosmetics, powder, eye shadow and other cosmetics … powder processing and manufacturing. Operation is simple to use for beginners of all operating procedures can be proficient in the shortest possible time.

Product Details

Four-operational effects than the traditional two-column actuation is more stable, it can be more evenly on the platen pressure on the mold surface, to ensure that products meet the compaction requirements of the industry.

All systems functional integration in which user-friendly operation and maintenance Panel user interface, which will integrate all the functions, in addition to outside the system as a whole to maintain beautiful, operation and maintenance of the system itself, compared with the traditional design better; and can provide more system information, user-friendly condition monitoring systems.

Convenient user-friendly user interface, in line with the needs of users, to provide more convenient and more comfortable to use interface, the increase in the new design are:

a. Actuating the way, to follow the job situation or needs of the users manual mode and automatic mode switching, provide another way to select an actuator.

b. preload timing design, the Department for powder particles of different chemical nature, under the pressure of time to adjust the cylinder on the expansion of the scope of the machine in use.

c. Loss of pressure timing design, under the pressure of the pressure becomes adjustable, with the dust fall timing of use, it can make the plate dwell time and increase downward pressure on the platen, make more of the powder compaction, to meet product requirements should be.

d. The design of the dust counter, can be set to the number of times pressed powder. Less sperm quality, the best choice for semi-dust system, do not ask for the number, but the product quality requirements of the industry has been concerned, price and quality SPU series is undoubtedly the best choice among excellent value for money.

Technical Parameter

| Name | Semi-automatic Powder Pressing Machine |

| Model | YT-260 |

| Article | powder,color face powder,eye shadow |

| Volume | depends |

| Filling | Piston pump,air compressor |

| Precision | ±1% |

| Pneumatic | 0.6-0.8Mpa |

| Caliber | ≥5mm |

| Capacity | 35bottles/min |

| G.W. | 420Kg. |

| Dimension | 1650mmL*1340mmW *1830mmH |

| Function | This is a sheer pneumatic filling machine for face powder, eye shadow powder etc. |

| Remarks | we have two kind of machine. Both are semi-automatic. But the new design machine is more advanced which is faster and more convenient to operate. |

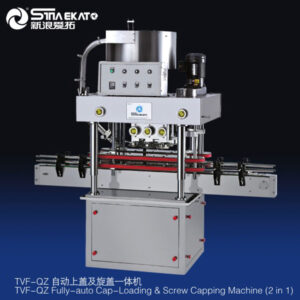

Relevant Machines

- RO Water Machine

- Bottle Washing Machine

- Bottle Drying Sterilizer

- Stainless steel storage tank

- Vacuum Homogenizer mixer

- Liquid Washing Homogenizing Mixer

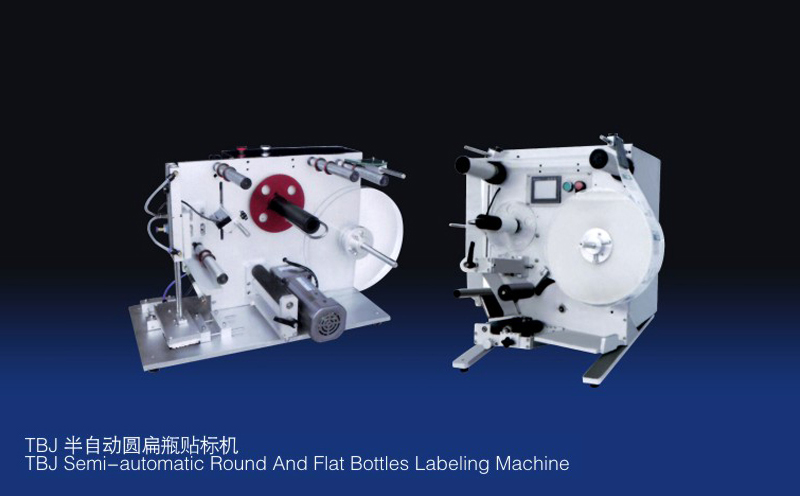

- Semi-auto labeling machine

- shrinking seal wrapping machine

Company Profile

With the solid backing of jiang su Province gao you city Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKAT chemical Machinery Co, Ltd. is a professional manufacturer of various types of cosmetic machinery and equjpment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, foodchemical industry, electronics, etc., serving many nationally and internationally famous enterprises suchas Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., ltd, Liangmianzhen GroupZhoneshan Perfect, Zhoneshan Jial, Guanedone Yanor, Guanedone Lafane. Beine Dabao, Japan Shiseidokorea charmzone, France shiting, Usa JB, etc.

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Our Project

Packing and Shipping

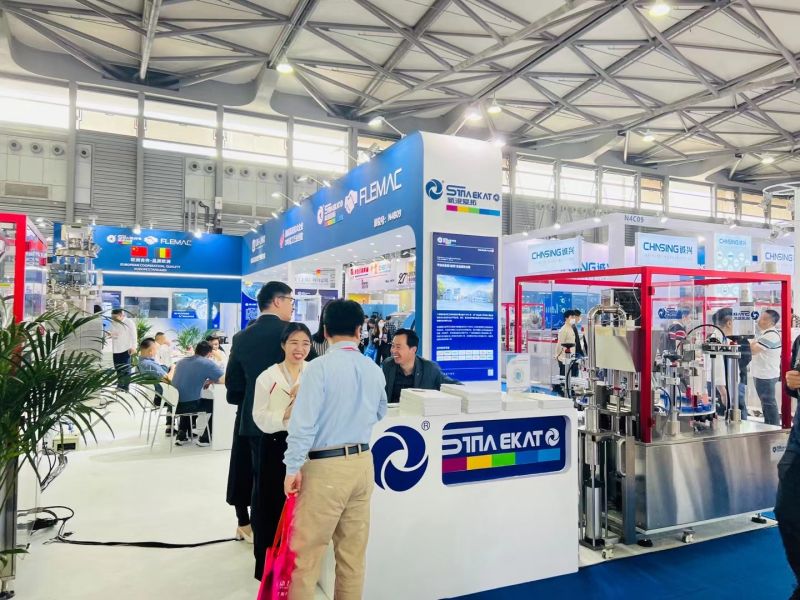

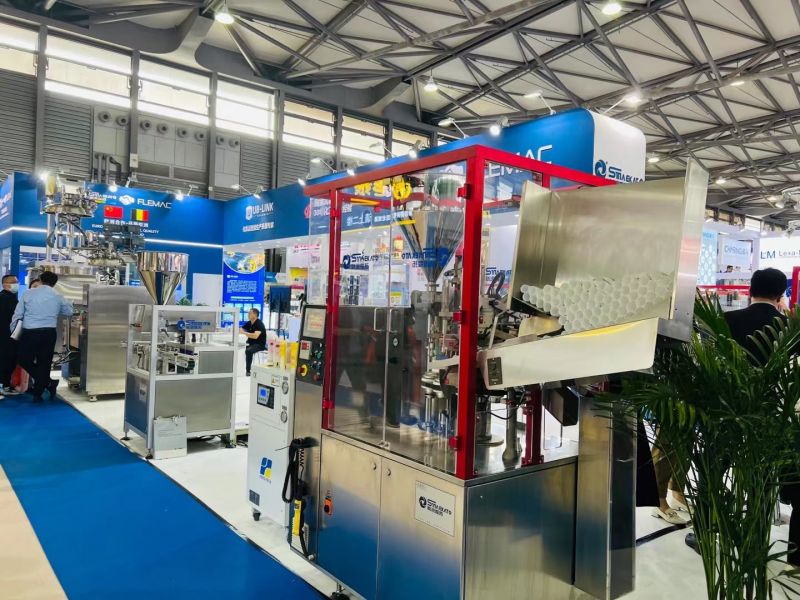

Exhibitions & Customers visit factory

Cooperative Customers

Material Certificate

Contact Person

Mrs Jessie Ji

Mobile/what’s app/wechat: +86 13660738457

Email: 012usinaekato.com

official website: http://www.sinaekato.group

Reviews

There are no reviews yet.